Titanium flange nuts are important components in various Industries and are known for their excellent strength, corrosion resistance, and lightweight properties. These nuts are often used in high-performance applications, especially in environments where strength and durability are important. As a precision CNC machining supplier headquartered in China, JeaSnn focuses on providing high-quality titanium flange nuts to meet the needs of various industries and ensure improved performance and reliability.

What is a titanium flange nut?

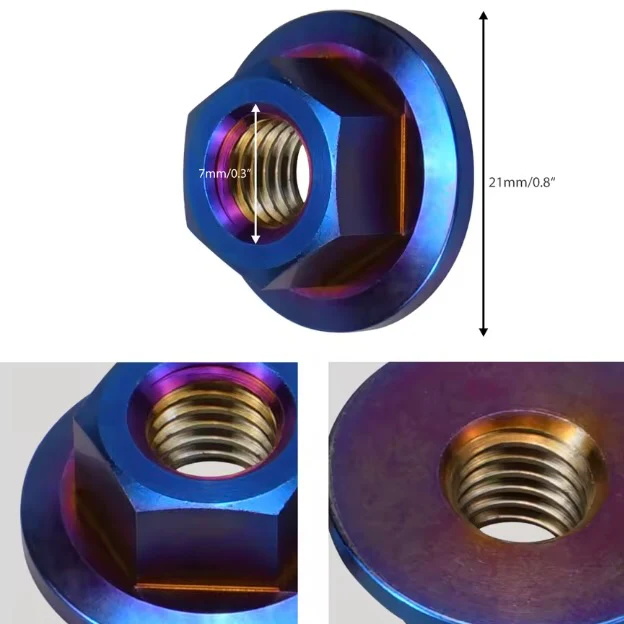

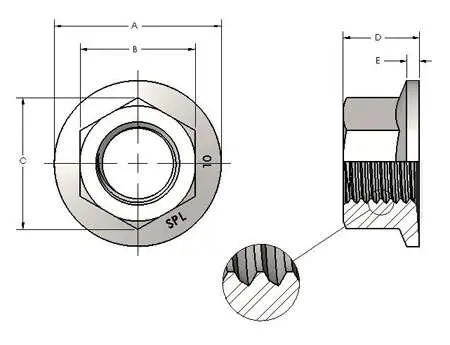

Titanium flange nuts are nuts with flanges that act as washers, providing additional contact area to distribute loads more evenly. The flange also prevents the nut from loosening under vibration conditions, so it performs particularly well in harsh environments. These nuts are made of titanium metal, which is known for its excellent strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Differences between titanium flange nuts and ordinary nuts

The main difference between titanium flange nuts and ordinary nuts is the Material and design. Ordinary nuts are usually made of steel, aluminum, or other metals, while titanium flange nuts are made of titanium alloy, which has greater strength and lighter weight. In addition, the flange design of titanium flange nuts provides additional stability and load distribution functions, which are not found in traditional nuts.

![]()

![]()

Advantages of Titanium Flange Nuts

High Strength-to-Weight Ratio: Titanium has an extremely good strength-to-weight ratio, making titanium flange nuts stronger and lighter than steel or aluminum alloy nuts.

Corrosion Resistance: Titanium is extremely resistant to corrosion and remains stable even under extreme conditions, such as exposure to salt water and high temperatures. This property makes titanium flange nuts particularly important in industries such as aerospace, marine, and automotive.

Durability: Titanium flange nuts are resistant to wear and can withstand high stress and wear in the harshest environments.

Biocompatibility: Titanium is non-reactive and hypoallergenic, making titanium flange nuts ideal for medical applications that require contact with the human body.

Application Areas of Titanium Flange Nuts

Titanium flange nuts are widely used in a variety of industries, including:

Aerospace: Titanium flange nuts are widely used in aircraft and spacecraft components due to their strength and high temperature resistance.

Automotive: In high-performance automobiles, titanium flange nuts are used to reduce weight while ensuring that strength is not compromised.

Marine: In marine environments, titanium's resistance to salt water corrosion makes it ideal for boats and submarines.

Medical devices: Titanium’s biocompatibility makes it ideal for medical implants and devices.

Sporting goods: Titanium flange nuts are also widely used in high-end bicycles, especially Track Bike hubs for racing, where performance and lightweighting are critical.

Manufacturing process of titanium flange nuts

The production of titanium flange nuts usually requires multiple precision steps. CNC (computer numerical control) machining technology is often used for precision manufacturing, ensuring that each nut meets strict specifications. The production process usually includes the following steps:

Material selection: High-quality titanium alloys (such as Ti-6Al-4V) are usually selected because of their excellent strength and corrosion resistance.

CNC Machining: The raw materials are fed into the CNC machine tool, and the desired nut shape is manufactured through precise cutting, forming and threading.

Heat treatment: Titanium flange nuts are heat treated to improve their mechanical properties.

Finishing: The last step is surface finishing to remove burrs or flaws and ensure that the nut surface is smooth and defect-free.

How CNC Machining improves Track Bike Hub performance

CNC machining plays a vital role in improving Track Bike Hub performance. By using high-precision CNC equipment, manufacturers can ensure the accuracy of hub components to ensure they fit perfectly. This not only allows for smoother operation, but also reduces friction and improves overall riding efficiency. When combined with the titanium flange nut, the Track Bike Hub becomes lighter, stronger and more durable, thereby improving the overall performance of the bicycle.

Key Materials and CNC Processing Technology

JeaSnn uses high-quality titanium alloys and advanced CNC processing technology to produce high-quality titanium flange nuts. The company focuses on precision machining to ensure that each nut meets the highest standards of durability and performance. Advanced CNC equipment is able to process complex shapes and fine designs with unmatched accuracy, making JeaSnn's products the first choice for precision-manufactured components in many industries.

JeaSnn Product Features

High Precision: Through advanced CNC processing technology, JeaSnn ensures that each titanium flange nut is manufactured to strict specifications with minimal tolerances.

Durability: JeaSnn's titanium flange nuts are made of high-quality titanium alloys with excellent strength and corrosion resistance, ensuring long-term and reliable use.

Customizable: JeaSnn provides customized solutions to meet customers' specific needs in size, shape and thread specifications.

Titanium flange nuts play a key role in multiple industries and are popular for their excellent strength, corrosion resistance and durability. Combined with CNC machining technology, these nuts are able to provide unparalleled precision and reliability. As a leading Chinese precision CNC machining supplier, JeaSnn is committed to providing high-quality, customizable titanium flange nuts to meet the specific needs of customers in various industries, from aerospace to sporting goods. With its high precision, durability and customized services, JeaSnn's titanium flange nuts are ideal for industries that require high performance and reliability.

English

English