As a professional CNC precision hardware processing supplier, JeaSnn provides high-quality stainless steel U-bolts, which are widely used in pipeline fixing, mechanical equipment installation, building structure reinforcement, automobile and ship accessories and other fields. Our U-bolts use advanced CNC processing technology to ensure high precision and high durability, and can be customized according to customer needs.

Material and corrosion resistance

JeaSnn mainly uses high-quality stainless steel materials such as 304, 316, and 316L:

304 stainless steel: has good corrosion resistance and is suitable for use indoors and in general environments.

316/316L stainless steel: contains molybdenum (Mo) elements, providing stronger corrosion resistance, suitable for marine environments, chemical equipment, and high humidity areas.

Corrosion resistance characteristics: anti-oxidation, acid and alkali resistance, rust resistance, suitable for long-term use, especially suitable for humid or harsh environments.

Features

High strength: using precision CNC Turning technology to ensure stable mechanical properties and high-strength load capacity.

Strong fatigue resistance: not easy to deform after long-term use, ensuring fixed stability.

Widely applicable: suitable for various Industries such as construction, pipelines, automobiles, ships, outdoor facilities, etc.

Customized service: different specifications, thread types, lengths and surface treatment methods can be processed according to customer needs.

Specifications and Dimensions

JeaSnn can provide a variety of standard and customized specifications, including but not limited to:

Thread type: Metric thread (M6-M20), American thread (1/4"-3/4")

U-shaped dimensions: pipe diameter, center spacing, and total length can be customized according to needs

Common application dimensions:

M8 x 40mm x 60mm

M10 x 50mm x 80mm

1/2" x 2" x 4"

Carrying capacity and strength

Tensile strength: Meets international standards and is suitable for high-load applications.

Shear resistance: Reinforced U-shaped bolts are suitable for heavy equipment and high-pressure environments.

Load test: Each batch of products undergoes rigorous mechanical testing to ensure safety.

Surface treatment and process

Polishing: Enhance surface smoothness, reduce friction, and improve aesthetics.

Passivation: Improve corrosion resistance and rust resistance.

Electroplating: Optional zinc plating, nickel plating, etc. to increase durability.

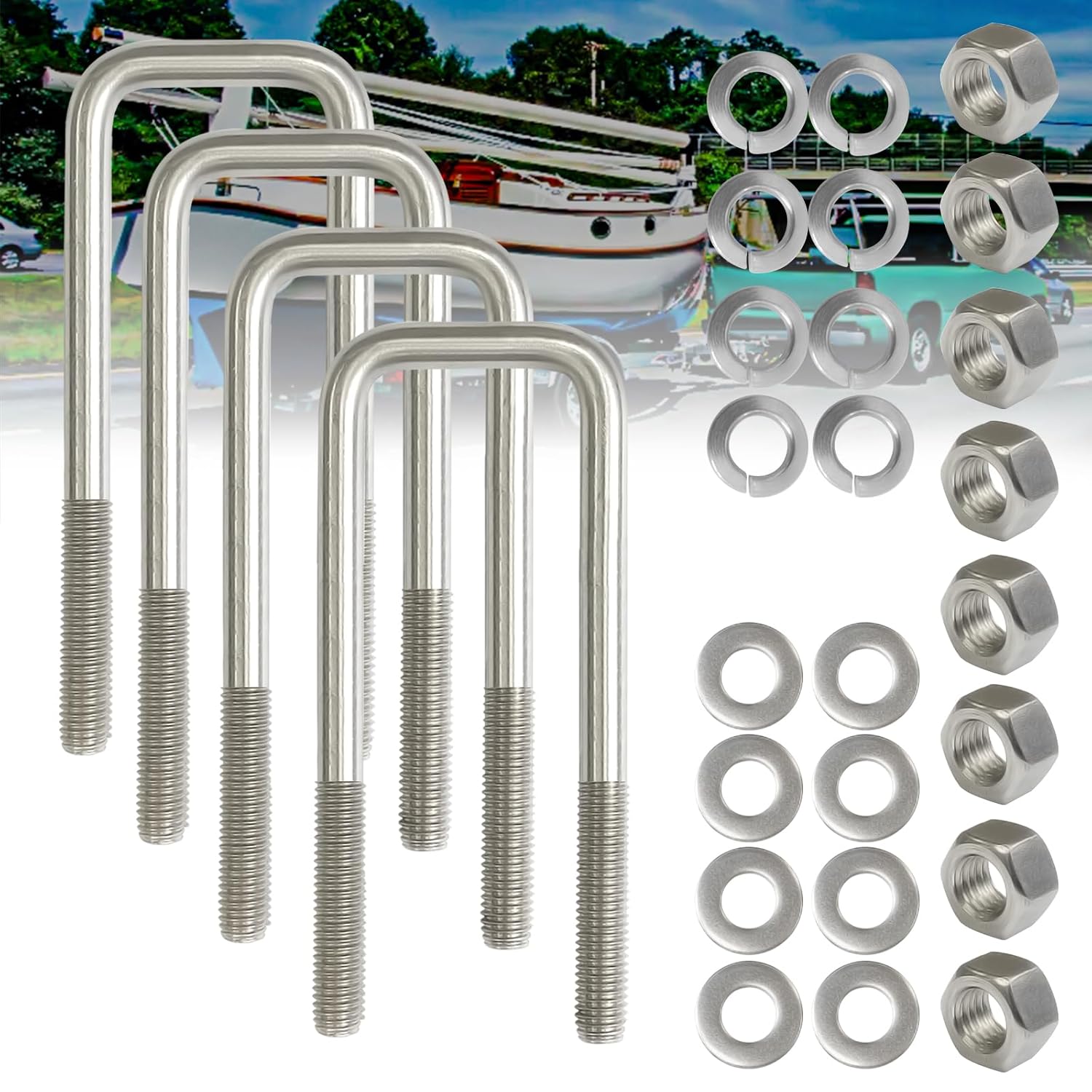

Installation and accessories

Standard accessories: Provide Nuts, washers, and fixing plates ensure a secure installation.

Easy-to-install design: Precision-machined threads for easy and quick installation.

Application scenarios: Can be used for pipe fixing, frame structure, equipment support, car modification, etc.

JeaSnn has a full set of CNC production equipment and complete Assembly Services, and can provide high-quality stainless steel U-bolts and customized solutions to meet the different needs of customers. If you need more specifications or customized solutions, please contact us!

FAQ

What materials do you offer for U-bolts?

We mainly offer U-bolts made of 304, 316, and 316L stainless steel. 304 stainless steel is suitable for general environments, while 316 and 316L stainless steel are suitable for more corrosive environments, such as marine and chemical industries.

Can the size of the U-bolts be customized?

Yes, we provide a full range of customization services. You can choose the pipe diameter, center spacing, total length, and thread specifications according to your needs. We support customized designs based on specific application scenarios.

What are the load-bearing capacities of your U-bolts?

Our U-bolts have a strong load-bearing capacity and are suitable for the installation of high loads and heavy equipment. Each order will undergo rigorous quality and strength tests to ensure stable use in high-pressure environments.

What is the surface treatment of your bolts?

We offer a variety of surface treatment options, including polishing, passivation, and electroplating (such as zinc plating, nickel plating, etc.). These treatments can effectively improve the corrosion resistance and aesthetics of the bolts, ensuring that they are not easy to rust after long-term use.

Is the U-bolt easy to install?

Our U-bolts are designed to be very easy to install, and the precision thread processing ensures that the installation process is simple and fast. We also provide matching nuts, washers and fixing plates to make the installation more stable.

What payment methods do you support?

We support a variety of payment methods, including bank transfer, credit card payment, PayPal, etc., to ensure a safe and fast transaction process.

What is the lead time for custom orders?

The lead time depends on the complexity and quantity of the order. Standard custom orders usually take 7-15 working days. If there is an urgent need, we can also provide expedited service to try to meet your time requirements.

Do you provide quality assurance for your products?

Yes, we provide quality assurance for each custom order. If there is a quality problem with the product, we promise free return and exchange within 30 days. At the same time, all products are accompanied by detailed test reports to ensure compliance with international standards.

Do you support small batch customization?

We support small batch customization, and you can customize U-bolts according to actual demand. Whether it is a small or large order, we can provide excellent service and products.

Do you provide international delivery service?

Yes, we provide international delivery service. No matter where you are, we can ensure that the products are delivered to your designated location on time and safely.

English

English