Inspection is a crucial step in ensuring product quality and performance in precision machining. By conducting inspections, we can verify whether parts meet design requirements and ensure that dimensional accuracy and geometric tolerances are up to standard. Inspections help to promptly identify defects during the machining process, such as insufficient surface roughness or shape errors, allowing for corrective actions to prevent defective products from reaching the market.

Inspection is not just part of quality control; it also plays a vital role in extending equipment lifespan and ensuring safety. In Industries such as aerospace, Medical devices, and automotive, the quality of precision components is directly related to the safety of equipment and personnel. Inspections can eliminate potential safety hazards and prevent accidents caused by defective parts. Additionally, by ensuring the precision and reliability of parts, inspections enhance the operational stability of equipment, reduce failure rates, and thus extend the service life of the equipment.

During production, inspections help us detect and resolve issues early on, reducing rework and scrap rates, and improving production efficiency. For JeaSnn, where production costs are high, inspections help save resources and time by ensuring that every part meets the expected quality standards. Moreover, inspections ensure that products comply with industry standards and regulatory requirements, enabling us to pass quality certifications, gain market access, and deliver high-quality products to our customers.

A robust inspection process helps build customer trust in our products and enhances our brand reputation. By ensuring the consistent quality of every part, JeaSnn earns long-term customer trust and strengthens its competitiveness in the market.

There are a wide variety of inspection equipment used for precision machined parts, primarily to ensure that the dimensional accuracy, shape accuracy, and surface roughness of the machined parts meet design requirements. Common inspection equipment includes:

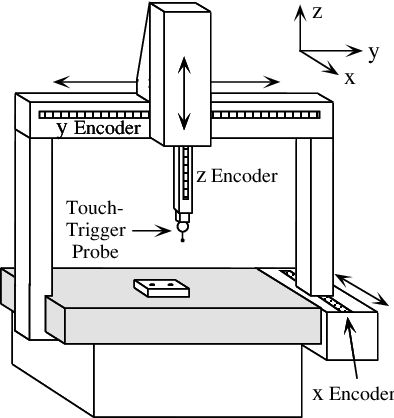

Coordinate Measuring Machine (CMM): Used for measuring the geometric dimensions and geometric tolerances of parts, featuring high-precision three-dimensional measurement Capabilities. It is suitable for complex-shaped parts.

Optical Image Measuring Instrument: Utilizes optical imaging technology to perform non-contact measurement of the external contours of parts. It is ideal for inspecting small parts and complex contours.

Laser Interferometer: Used to measure surface morphology and tiny geometric errors of parts, offering extremely high measurement precision.

Profilometer: Used to measure the surface profile and roughness of parts, commonly applied in high-precision surface inspections.

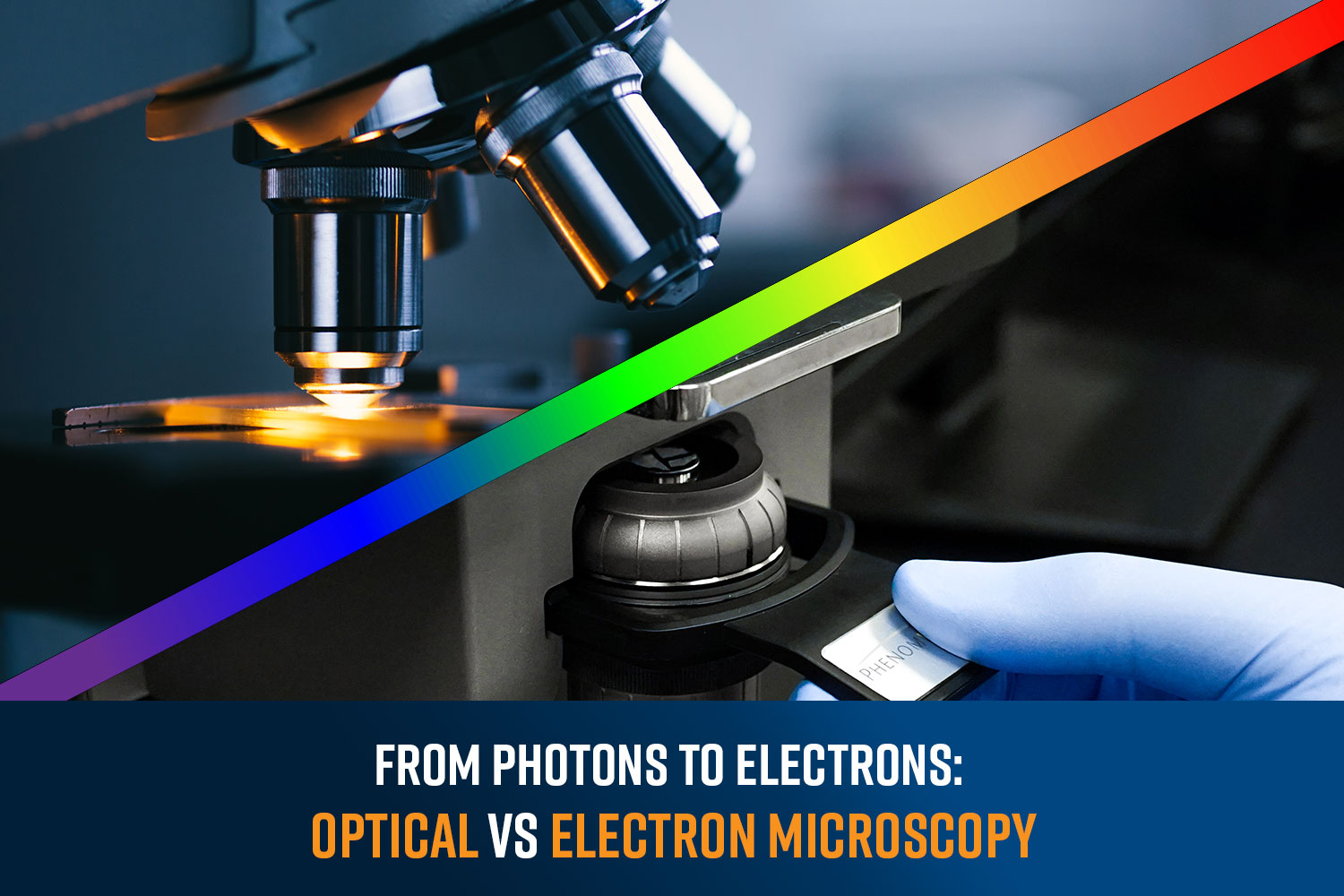

Microscope: Includes optical microscopes and electron microscopes, used for inspecting microscopic structures, surface defects, and fine dimensions, especially suitable for small parts.

Roughness Tester: Used to measure the surface roughness of parts, obtaining roughness parameters by scanning the surface with a stylus.

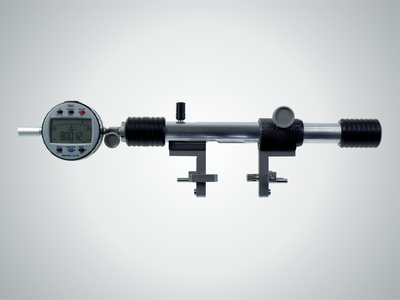

Roundness Tester: Specifically designed to measure the roundness error of parts, ensuring the precision of circular parts such as bearings and gears.

Hardness Tester: Used to measure the Material hardness of parts, with common types including Rockwell hardness testers and Vickers hardness testers.

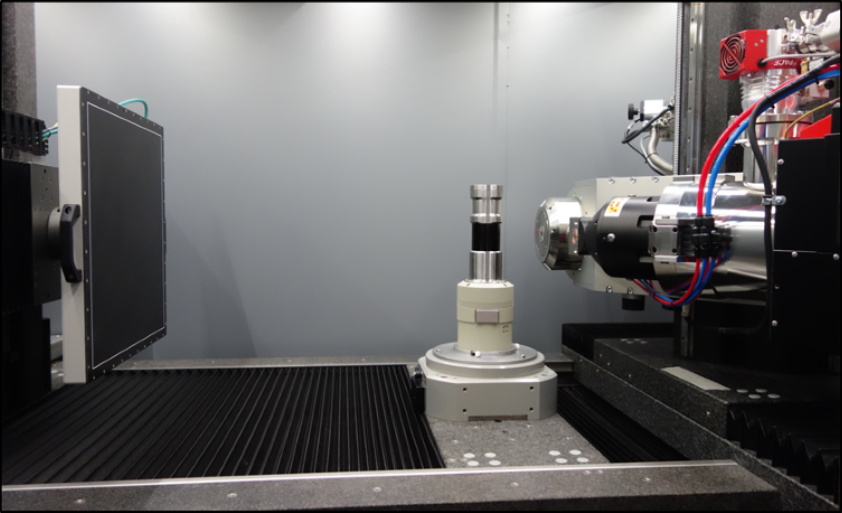

X-ray CT Scanner: Provides three-dimensional imaging of parts, used to inspect internal structures, defects, or complex shapes.

Pneumatic Measuring Instrument: Measures the diameter and geometric tolerances of parts using airflow, suitable for high-precision small hole inspections.

Each of these inspection devices has its advantages, and the appropriate equipment is typically selected based on the precision requirements and inspection needs of the machined parts.

JeaSnn has comprehensive inspection equipment to ensure the highest quality of precision machining. With advanced tools such as coordinate measuring machines (CMMs), optical image measuring instruments, laser interferometers, and X-ray CT scanners, JeaSnn guarantees that each part meets strict standards for dimensional accuracy, form accuracy, and surface roughness. Our state-of-the-art equipment can accurately measure complex shapes, microstructures, internal defects, and material hardness, ensuring that its products meet the highest industry standards. By utilizing these cutting-edge inspection technologies, JeaSnn consistently provides reliable, high-quality hardware solutions to meet the diverse needs of its customers.

English

English