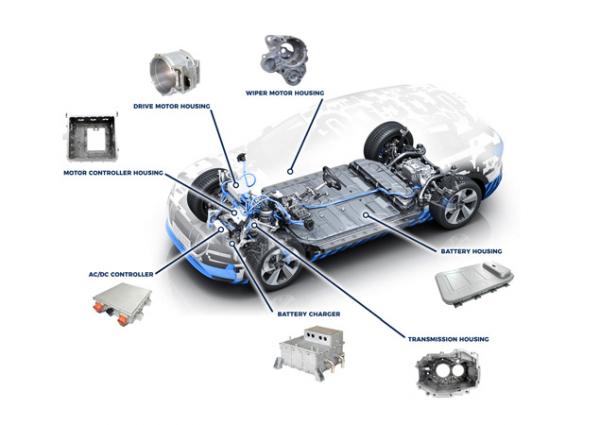

Electric vehicle (EV) component machining refers to the precision manufacturing of components designed specifically for electric vehicles. These components play a vital role in ensuring the efficiency, performance, and safety of electric vehicles, and include components such as battery housings, motor housings, heat sinks, and power electronics. Custom machining of EV components involves the use of advanced CNC machines to meet the tight tolerances, high performance, and Material specifications required by the EV industry.

Features

High Precision: EV components often have tight tolerances due to their critical functions, such as heat dissipation, electrical conductivity, and energy storage. Precision machining ensures that these components meet the specifications required for smooth performance.

Diverse Materials: EV components are made from a variety of materials, including aluminum, titanium, high-strength steel alloys, and composites. These materials are selected for their light weight, high strength, and electrical conductivity, all of which are critical to the performance of electric vehicles.

Complex Geometries: Many EV components have complex shapes that require advanced machining techniques, such as 5-axis CNC Machining, to create precise and complex features.

Durability: EV components must be durable and able to withstand a variety of conditions, including high temperatures, vibration, and mechanical stress. Machining these components to exacting standards ensures longevity and reliability.

Advantages

Optimize Performance: Custom machining ensures that each component performs at its best, whether it’s a battery housing that protects the battery pack or a motor housing that effectively dissipates heat.

Reduce Weight: As electric vehicles pursue greater energy efficiency, lightweight components are critical. Precision machining ensures that parts are not only lightweight, but also strong and durable.

Enhance Safety: Many electric vehicle components, such as battery housings and motor components, must meet stringent safety standards. Custom machining helps ensure that manufactured parts protect passengers and critical electronics.

Improve Efficiency: Precision machining ensures that parts fit perfectly, reducing friction and inefficiencies in power transmission and heat management, thereby improving the overall performance of the vehicle.

Common Problems

Material Challenges: Electric vehicle components often use materials that are difficult to machine, such as composites or high-strength alloys. These materials wear out tools more quickly and require specialized equipment and techniques.

Thermal Management: Many electric vehicle components, especially those related to batteries and motors, generate a lot of heat. Effective machining techniques must ensure that these components are optimized for heat dissipation.

Tight tolerances: EV components often require extremely tight tolerances. Even small deviations can affect performance, so achieving these tolerances consistently is a challenge.

Cost control: Precision machining, especially for complex EV components, can be costly. Balancing high-quality machining with cost-effectiveness is critical for mass production.

Services JeaSnn Hardware can provide

High-precision CNC Machining: JeaSnn Hardware specializes in CNC machining of EV components, providing precision parts with tight tolerances and high quality, such as battery housings, motor components, and power electronics housings.

Material selection and customization: JeaSnn Hardware offers a wide range of materials, including aluminum, titanium, and carbon composites, ensuring that components are made from the best materials for their specific applications, thereby optimizing strength, weight, and heat management.

Complex part machining: Using advanced CNC technology, including 5-axis machining, JeaSnn Hardware can produce the complex geometries required for EV components, ensuring that each part fits perfectly into the EV system.

Rapid Prototyping and Production: With rapid prototyping Capabilities, JeaSnn Hardware can quickly deliver prototypes for testing and validation, and efficiently scale up for full production once the design is approved.

Comprehensive Quality Control: JeaSnn Hardware ensures that all EV components undergo rigorous quality checks to meet the highest standards of performance, safety, and durability.

Expert Consulting: Our experienced engineers work closely with customers to understand their needs and provide custom machining solutions, whether for a single component or large-scale production.

In short, JeaSnn Hardware provides custom automotive machining services that address the unique challenges of the electric vehicle industry, from precision part manufacturing to material selection and advanced machining technologies. We are committed to providing high-performance, durable, and cost-effective solutions for EV components.

English

English