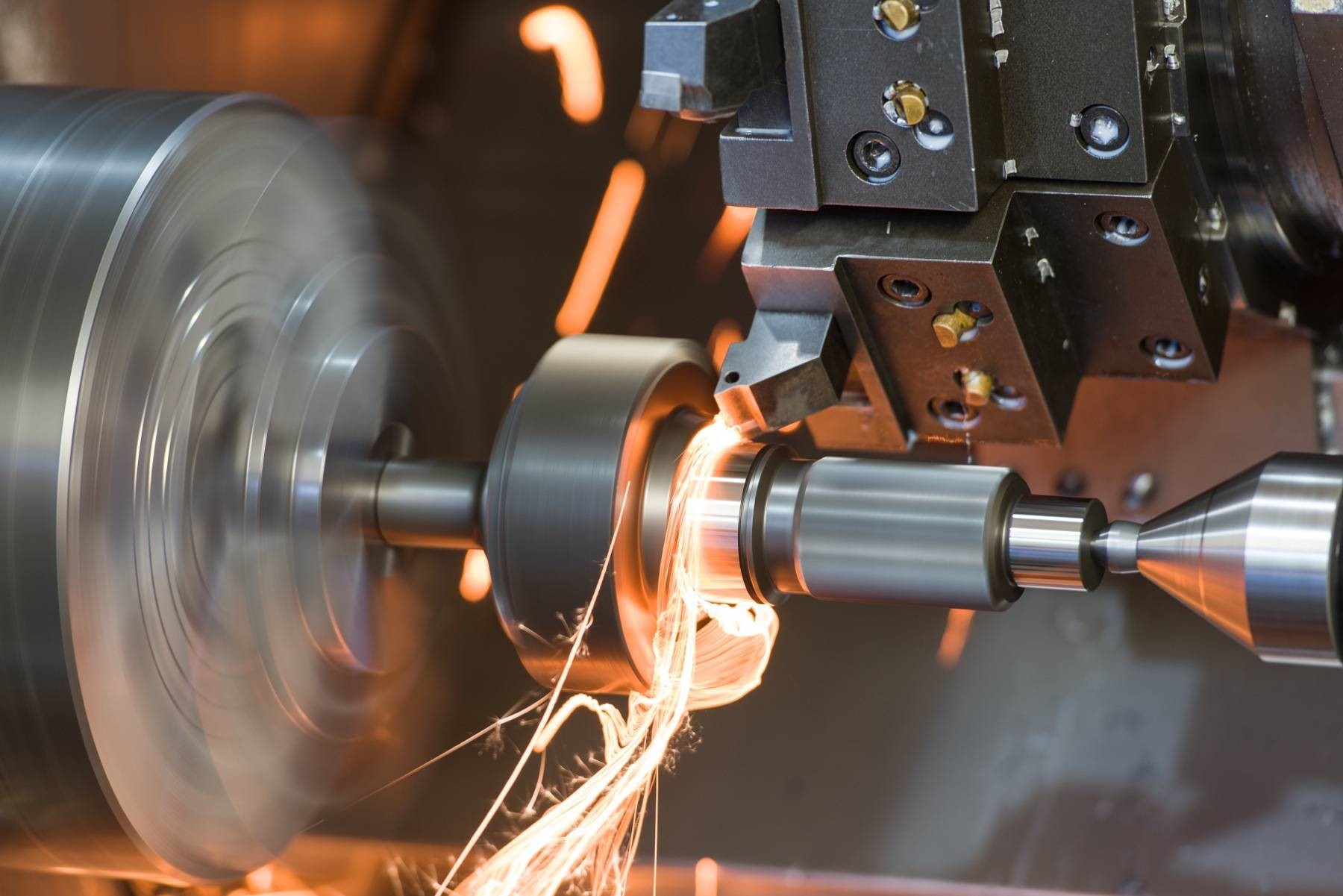

The Role of CNC Turning in Precision Machining

In precision machining, CNC Turning machines play a crucial role. By using a computer numerical control (CNC) system to precisely control the movement of cutting tools, CNC turning achieves high-precision machining and can manufacture various complex geometries, including external cylinders, internal bores, tapers, and threads. The automation Capabilities of CNC turning machines ensure consistency and repeatability in machining, while also improving production efficiency and reducing costs. These machines provide excellent surface quality, reducing the need for subsequent processing. Their flexible programming and adjustment capabilities make them suitable for a wide range of Materials and machining tasks. Moreover, modern CNC turning machines are equipped with advanced sensors and monitoring systems, enhancing the reliability and safety of the machining process. As a result, CNC turning is widely used in aerospace, automotive manufacturing, electronics, and medical devices.

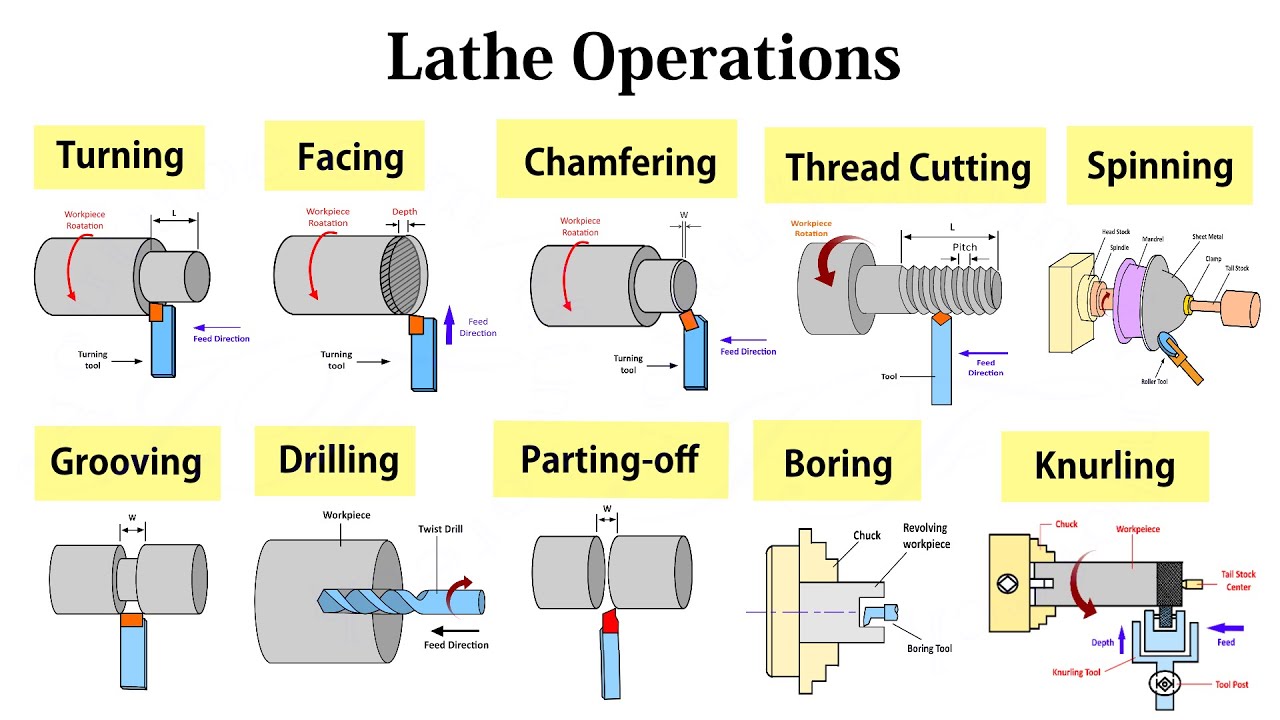

Here are some common CNC turning types:

External Turning: Machining the external cylindrical shape of the workpiece, used to produce external circular parts such as shafts and rods.

Internal Turning: Machining the cylindrical hole inside the workpiece, used to make internal holes or grooves.

Parting Off: Cutting the workpiece from the main block by a turning tool, usually used to separate the part from the long material.

Thread Turning: Cutting threads on the workpiece, used to produce threaded parts such as bolts and nuts.

Taper Turning: Machining a tapered shape or inner hole to make tapered parts or transition sections.

Profiling: Machining the workpiece according to a specific profile or shape, often used for complex shape processing.

Chamfering: Chamfering the edge of the workpiece to remove sharp edges and improve appearance or assembly.

Grooving: Cutting grooves on the surface of the workpiece, used to make slots, locating grooves, etc.

Face Milling: Although milling is traditionally performed on a milling machine, CNC turning machines can also perform face milling to machine the flat surface of a workpiece.

Cutting and Shaping: Includes cutting and shaping the workpiece to meet design requirements.

These turning types can be used alone or in combination to complete complex machining tasks. CNC turning machines are widely used in the manufacturing industry because they are programmed to achieve high-precision and repeatable machining.

JeaSnn's CNC turning supports a wide range of material options, including:

Aluminum parts: 2024, 5052, 5083, 6061, 6061-T6, 6063, 6082, 7075, etc.

Stainless steel/steel parts: SUS303, SUS304, SS316, SS316L, 420, 430, 17-4PH, 1214L/1215/4140/SCM440/40CrMo, etc.

Brass/copper/bronze parts: HPb63, HPb62, HPb61, HPb59, H59, H62, H63, H65, H68, H70, H80, H90, C110, C120, C220, C260, C280, C360, etc.

Plastic parts: polyoxymethylene (POM), nylon (PA), polycarbonate (PC), acrylic (PMMA), polypropylene (PP), polyvinyl chloride (PVC), polyurethane (PU), high-density polyethylene (HDPE), polyvinylidene fluoride (PVDF), ABS, PTFE, PEEK, etc.

The support of these materials enables JeaSnn to meet various processing needs and is suitable for different industrial applications.

Here are the characteristics of materials commonly used in JeaSnn’s CNC turning:

Aluminum:

2024: High strength and good fatigue resistance, suitable for aerospace applications, but has lower corrosion resistance.

5052: Excellent corrosion resistance and good formability, ideal for marine and automotive parts.

5083: Outstanding corrosion resistance and high-temperature durability, commonly used in marine environments.

6061: Well-rounded performance with good strength and corrosion resistance, suitable for structural components and engineering applications.

6061-T6: Heat-treated for higher strength, used for high-strength structural components.

6063: Good surface finish and formability, widely used in architectural and decorative applications.

6082: High strength and good corrosion resistance, suitable for engineering and structural applications.

7075: Extremely high strength, used in aerospace and high-strength structural components, but with lower corrosion resistance.

Stainless Steel/Steel:

SUS303: Excellent machinability and corrosion resistance, suitable for mechanical parts and precision machining.

SUS304: A widely used general-purpose stainless steel with good corrosion and heat resistance.

SS316: Better corrosion resistance than SS304, suitable for chemical processing and marine environments.

SS316L: Low-carbon version of SS316, suitable for welding applications.

420: High hardness, commonly used for tool manufacturing and hard-wearing components.

430: Good corrosion resistance and heat resistance, used in household appliances and automotive parts.

17-4PH: Good strength and corrosion resistance, suitable for high-strength and corrosion-resistant engineering applications.

1214L/1215: High machinability, suitable for precision machining and high-volume production.

4140: Alloy steel with high strength and good wear resistance, widely used in mechanical components.

SCM440: Alloy steel with good strength and wear resistance, suitable for automotive and mechanical applications.

40CrMo: Alloy steel with high strength and toughness, used in high-load and impact applications.

Brass/Copper/Bronze:

HPb63, HPb62, HPb61, HPb59: Various brass alloys with good machinability and corrosion resistance, used in electronic contacts and valves.

H59, H62, H63: Commonly used for mechanical processing and architectural decoration.

H65, H68, H70, H80, H90: High-strength brass, used for manufacturing high-strength mechanical parts.

C110: Pure copper with excellent electrical conductivity, used in electrical contacts.

C120: High-conductivity copper for electrical applications.

C220, C260, C280: Various copper alloys, used for manufacturing wear-resistant parts and electronic components.

Plastic:

POM (Polyoxymethylene): Excellent mechanical properties and wear resistance, suitable for gears and sliding components.

PA (Nylon): High strength and wear resistance, used for mechanical parts and gears.

PC (Polycarbonate): High strength and transparency, used in optical and safety applications.

PMMA (Acrylic): Transparent and weather-resistant, widely used in lighting and display applications.

PP (Polypropylene): Good chemical resistance, used in packaging and automotive parts.

PVC (Polyvinyl Chloride): Corrosion-resistant and wear-resistant, used in pipes and construction materials.

PU (Polyurethane): Good elasticity and wear resistance, used for seals and elastomers.

HDPE (High-Density Polyethylene): Good chemical resistance and high strength, used in pipes and containers.

PVDF (Polyvinylidene Fluoride): Excellent chemical resistance and high-temperature stability, used in chemical and medical applications.

ABS (Acrylonitrile Butadiene Styrene): Good impact strength and machinability, widely used in consumer electronics and automotive parts.

PTFE (Polytetrafluoroethylene): Exceptional chemical resistance and high-temperature stability, used in seals and corrosion-resistant applications.

PEEK (Polyether Ether Ketone): High strength and heat resistance, suitable for aerospace and medical applications.

JeaSnn's precision machining services offer exceptional machining capabilities for all types of aluminum, stainless steel, brass, copper, bronze, and plastics. Our wide selection of materials includes high-strength aluminum alloys such as 2024 and 7075, corrosion-resistant stainless steels such as SUS316 and SUS304, and various brass and copper alloys including HPB63 and C110. In addition, we use advanced plastics such as POM, Nylon, and PEEK to meet the needs of a variety of industrial applications.

Our CNC turning services are characterized by high precision, consistency, and efficiency, ensuring that each component meets strict quality standards and design specifications. Whether for aerospace, automotive, marine, or electronic applications, JeaSnn combines cutting-edge technology with skilled craftsmanship to provide reliable and high-quality machining solutions.

English

English