As a CNC precision machining manufacturer, JeaSnn understands that choosing the right CNC Machining service is crucial for producing high-quality auto parts. In the Automotive industry, where precision, durability, and functionality are essential, selecting a reliable CNC Machining provider can make a significant difference in the final product’s performance and reliability.

1. Industry Expertise and Experience

The first consideration when selecting a CNC machining service is their expertise in manufacturing auto parts. Automotive components have unique requirements in terms of precision, strength, and Material properties. A reliable CNC machining provider like JeaSnn should have a proven track record of producing high-precision auto parts, such as engine components, transmission parts, and suspension elements. Experience in working with complex geometries and tight tolerances is vital in ensuring your parts meet the industry’s rigorous standards.

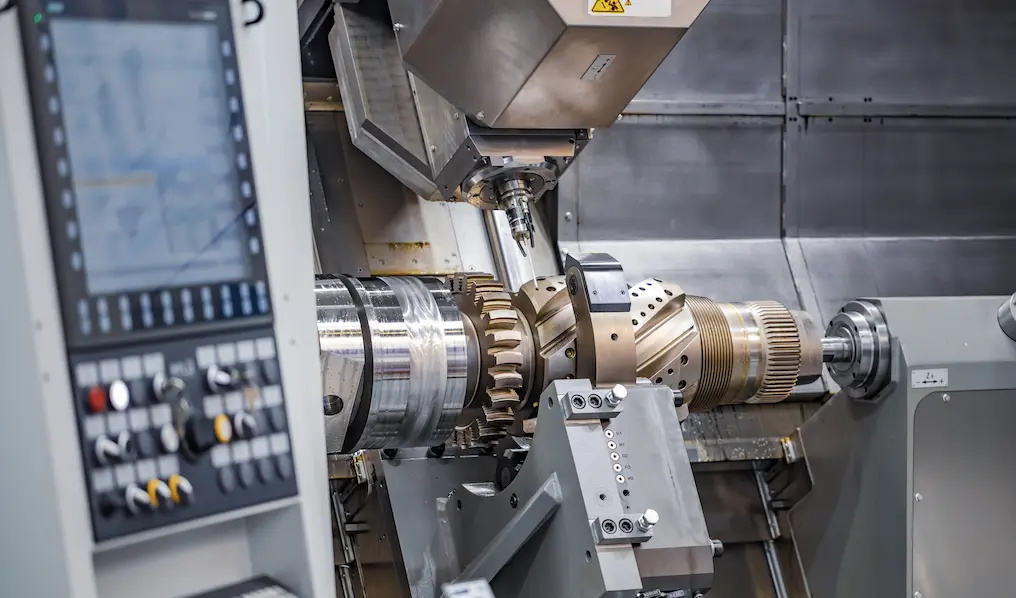

2. Advanced Equipment and Technology

CNC machining is a highly technical process, and the quality of the machinery used directly affects the quality of the auto parts produced. A good CNC machining service provider must have advanced CNC equipment, including multi-axis CNC mills, CNC lathes, and precision grinding machines. At JeaSnn, for example, we use state-of-the-art equipment capable of machining a variety of materials, such as steel, aluminum, and titanium, to meet the unique needs of automotive components. Having modern equipment ensures higher precision, faster production, and the ability to handle complex designs with ease.

3. Material Capability

Auto parts are made from various materials, including metals, alloys, and composites, each requiring specific machining techniques. When selecting a CNC machining service, ensure they have experience working with automotive-grade materials such as high-strength steel, aluminum alloys, and titanium. A good CNC manufacturer should also be able to source high-quality materials and provide material certification to meet your part’s performance requirements. For instance, JeaSnn can process materials with specific hardness or tensile strength to ensure your parts are durable and meet all safety regulations.

4. Precision and Quality Control

Quality is paramount when manufacturing auto parts, and CNC machining offers high precision and accuracy. However, not all CNC machining providers have the same level of precision. At JeaSnn, we adhere to strict quality control standards to ensure that each part meets precise specifications. We use advanced tools like Coordinate Measuring Machines (CMM) to verify dimensions and check tolerances with precision as tight as ±0.01mm. Additionally, we implement various inspections such as material tests, surface roughness checks, and mechanical property testing to ensure each part’s functionality and durability.

5. Customization and Prototyping

The automotive industry often requires customized solutions for unique vehicle models or performance features. Look for a CNC machining service that offers flexibility in custom machining and prototyping. Providers should be able to manufacture both low-volume custom parts and large-scale production runs. At JeaSnn, we excel in creating custom automotive parts, including prototype development to validate designs before full-scale production. Our quick turnaround times on prototypes help our clients fine-tune their designs efficiently.

6. Lead Times and Scalability

In the automotive industry, time-to-market can be a critical factor. Choosing a CNC machining service that can meet your production timelines is essential. A reliable provider should offer clear communication about lead times and the ability to adjust production schedules if necessary. At JeaSnn, we maintain flexible production schedules to meet tight deadlines, and our scalable production process ensures that we can handle both small and large batch orders efficiently.

7. Cost Efficiency

While cost is always an important factor, it should not be the sole consideration when choosing CNC machining services. It is crucial to evaluate the value that the provider offers. For instance, at JeaSnn, we focus on delivering high-quality machining at competitive prices, ensuring that customers get a balance of cost-efficiency and precision. Avoid opting for the cheapest option if it compromises part quality, as this can lead to costly repairs and rework in the long run.

8. Customer Support and Communication

Finally, strong customer support and clear communication are vital in the CNC machining process. A good provider will keep you informed about the progress of your order, address any concerns promptly, and offer ongoing support after delivery. At JeaSnn, we believe in building strong relationships with our clients by providing responsive customer service and technical support. Whether you need design assistance, production updates, or post-production feedback, our team is always available to help.

Choosing the right CNC machining service for auto parts manufacturing is essential to achieving high-quality, durable, and cost-effective components. By considering expertise, equipment, material capability, precision, customization options, lead times, and customer support, you can ensure that your parts meet the automotive industry’s stringent standards. At JeaSnn, we are dedicated to providing top-tier CNC precision machining services that meet your needs, whether for custom prototypes or large-scale production.

English

English