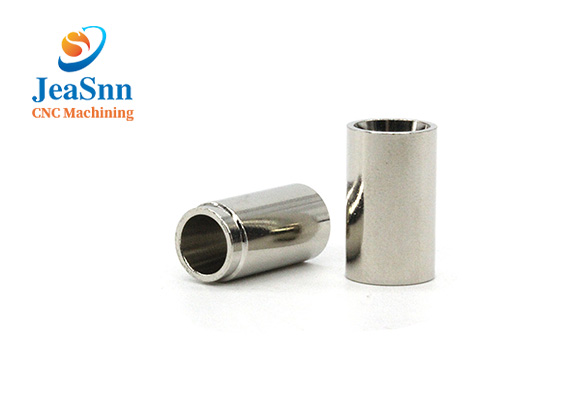

CNC Steel Bushings are high-precision steel bushings produced by computer numerical control (CNC) technology. Bushings are a common mechanical component and are widely used in mechanical equipment to carry, support and reduce friction. CNC (computer numerical control) technology makes the manufacturing process of steel bushings more precise, efficient and able to meet the needs of mass production. As a professional steel bushing manufacturer, JeaSnn is able to provide high-quality and high-precision CNC steel bushings for various Industries and applications with its advanced production processes and equipment.

The production of CNC steel bushings relies on highly automated and precisely controlled processing machines. Common processing machines include:

CNC lathes: used for turning metal Materials, removing excess material through tools, and accurately controlling the diameter, length and shape of parts.

CNC Milling machines: suitable for more complex processing of workpieces, capable of plane milling, slot milling and other complex shape cutting.

CNC drilling machines: used to accurately drill holes in steel bushings to ensure the accuracy and consistency of each hole position.

CNC grinding machine: used for high-precision surface polishing and precision adjustment to ensure that the size and surface quality of the bushing meet the requirements.

CNC processing technology enables the dimensional tolerance, geometry and surface quality of each bushing to meet strict requirements, and is suitable for industrial applications requiring high precision.

The materials commonly used for CNC steel bushings mainly include:

Carbon steel: Carbon steel is one of the most commonly used materials for manufacturing bushings. It has high strength and toughness and low cost. It is suitable for applications with general loads and low corrosion resistance requirements.

Alloy steel: Alloy steel improves the mechanical properties, wear resistance and high temperature resistance of the material by adding other elements (such as chromium, nickel, molybdenum, etc.). It is suitable for applications that require higher strength and durability.

Stainless steel: Stainless steel has excellent corrosion resistance and high temperature resistance, and is suitable for applications with high requirements for anti-corrosive environments.

Tool steel: Tool steel has extremely high hardness and wear resistance, and is suitable for manufacturing high-load, long-term use bushings.

The choice of material depends on the application requirements, working environment and load requirements of the bushing.

The precision of CNC steel bushings is one of the most critical factors in the manufacturing process. Precision directly affects the performance of the bushing in the application. Through CNC processing technology, the manufacturing tolerance of the bushing can usually be controlled at ±0.005 mm or even higher precision, ensuring that the size and geometry of each bushing are extremely consistent and accurate. Common precision requirements include:

Dimensional accuracy: Control the key dimensions of the bushing, such as the inner diameter, outer diameter, length, thickness, etc., to ensure the matching degree between the parts and the equipment.

Geometric accuracy: Including surface flatness, verticality, roundness, coaxiality, etc., to ensure the smooth operation of mechanical parts.

Surface roughness: The surface roughness is usually controlled between Ra0.8 and Ra3.2, which can effectively reduce friction and extend service life.

Surface treatment is crucial to the performance of CNC steel bushings. Through different surface treatment processes, the wear resistance, corrosion resistance and aesthetics of the bushing can be improved. Common surface treatment methods include:

Heat treatment: Change the crystal structure of steel through heating and cooling processes to improve the hardness and wear resistance of the material. Common heat treatment methods include quenching, tempering and annealing.

Electroplating: Electroplating metal coatings (such as nickel, chromium, etc.) onto the surface of steel bushings to enhance their corrosion resistance and surface finish.

Phosphating: Forming a phosphate film on the surface of steel parts can improve corrosion resistance and reduce wear.

Spray coating: Spraying wear-resistant and oxidation-resistant coatings on the surface of bushings to improve wear resistance and corrosion resistance.

Surface treatment can not only enhance the performance of bushings, but also extend their service life and reduce maintenance costs.

CNC steel bushings are widely used in multiple industries, including but not limited to:

Automotive industry: used in important components such as engines, transmissions, and suspension systems, which can effectively reduce wear and extend service life.

Mechanical equipment: such as sliding parts in precision machine tools, bearings and bushings in transmission systems, which require high precision and high durability.

Aerospace: Bushings used in aircraft engines and structural parts require high precision, high temperature resistance and corrosion resistance.

Construction engineering: Bushings in large equipment such as bridges and tower cranes have high load-bearing capacity requirements and are often used in scenes with large loads.

Mining and heavy machinery: In the fields of mining machinery, metallurgical equipment, etc., high-strength and wear-resistant steel bushings are used to carry heavy loads and high-frequency operations.

CNC steel bushings have the following significant features:

High precision: CNC processing technology ensures that each bushing can meet strict dimensional tolerances and surface quality requirements.

High strength: High-quality steel is used, with good strength and wear resistance, suitable for high-load and high-impact environments.

Strong durability: Through heat treatment and surface treatment processes, the bushing can still maintain a long service life in a variety of complex working environments.

Customization capability: According to customer needs, bushings of different sizes, different materials, and different surface treatments can be provided to meet personalized customization requirements.

In terms of usage scenarios, CNC steel bushings are suitable for various occasions that require bearing, support and friction reduction, especially in high-speed operation, heavy load and harsh working environment, the role of bushings is crucial.

As a professional CNC steel bushing manufacturer, JeaSnn relies on advanced production technology, precision processing equipment and strict quality control to provide high-quality bushings suitable for various industrial applications. Through precise processing, tolerance control and surface treatment, we ensure that each bushing has excellent performance and reliability, meeting the needs of different industries for high-strength and high-precision parts.

English

English