Introduction

Aluminum machining is one of the most common Materials in the CNC machining industry. Aluminum material is soft, ductile, and non-magnetic, making it a very easy to machining. Reading this article, you will learn about CNC aluminum machining, its advantages, and applications.

Overview of CNC Aluminum Machining

CNC aluminum machining is also known as precision alloy aluminum CNC machining. It is a relatively advanced and commonly used machining method in the metal manufacturing industry.

Aluminum CNC machining is a method of machining various aluminum parts using CNC machines. A set of machining programs are compiled by computer, and workpiece machining is performed digitally, including cutting, drilling, tapping, etc., which rely on CNC machine operation.

CNC aluminum machining compared to the technical advantages of traditional processing, you can use a variety of processing methods, component shape diversification, and high precision, fast machining speed, which can ensure fast and on-time delivery of the parts for customers. CNC machined aluminum products have high precision, tighter tolerances, stable quality, lightweight and lower shipping costs.

Advantages of CNC Aluminum Machining Service

It can reduce the aluminum parts production and processing operation process steps, even if a very complex process production and processing is also very efficient, saving labor costs.

Significantly reduce the number of workpiece fixtures, processing complex shape parts does not need complex workpiece fixtures. If you want to change the shape and size of the part, you only need to modify the machining program.

It can be processed by conventional methods difficult to process complex surfaces, even machining some unobservable custom metal parts.

Higher production efficiency in Multi-species, small batch projects, can reduce the production machine, and machine tool adjustment time.

Aluminum is resistant to scratches and corrosion under common marine and atmospheric conditions. You can enhance these properties by anodized finishing. Different aluminum materials series have varied corrosion resistance.

Since aluminum CNC machining is a subtractive manufacturing process, a large number of chips are generated during machining. Aluminum is highly recyclable, which means it takes relatively little energy, effort and cost to recycle.

CNC Aluminum Parts Application Different Industries and Cases

Precision aluminum machining is a key technology in modern manufacturing. Its applications cover a wide range of industries and benefit from the unique properties of aluminum and precision CNC machining.

Aerospace Industry

In the aerospace industry, CNC aluminum machining is used for components that require lightweight, high strength and durability. Aluminum is lighter than steel, making it ideal for aircraft structural components, such as wing panels and cockpit instruments. Precision CNC machining ensures that these components meet the stringent safety and performance standards required by the aerospace industry.

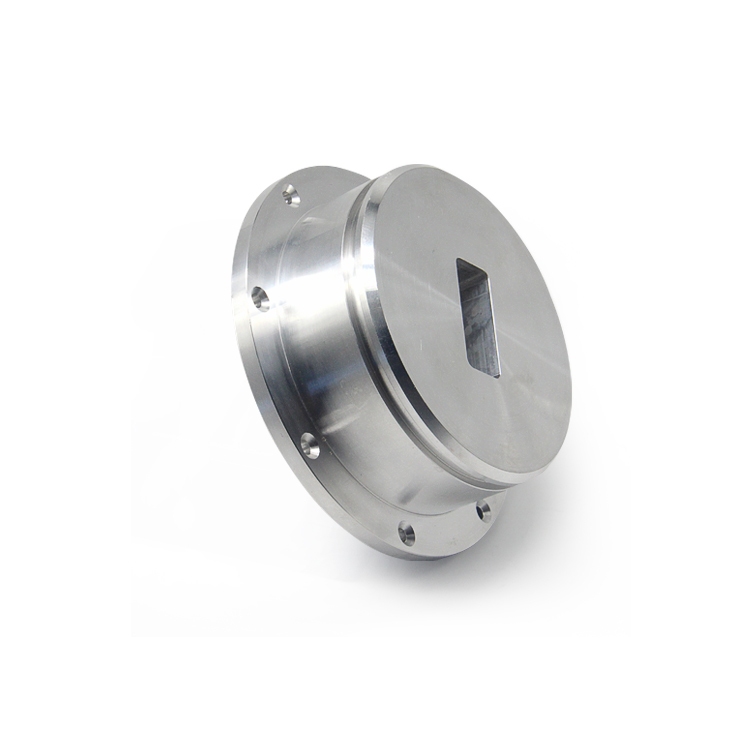

Case Study: A notable success story is a collaboration with a leading aerospace manufacturer to produce aluminum cockpit instrument accessories and seat accessories for them. Using advanced 3 4 5 axis CNC machining centers, components are produced to meet stringent aerospace standards. Here are some samples for your reference.

Lighting Industry

Application: CNC aluminum processing parts play a vital role in the lighting industry. They must be able to withstand harsh weather conditions while maintaining their performance and appearance. We use this processing technology to produce complex pour housings, glare shields, bezel cover caps, heat sink and other lighting accessories. The plasticity of aluminum materials allows designers to achieve more fluent and modern lighting designs, and the high precision of CNC processing ensures the precise implementation and high-quality surface treatment of these designs.

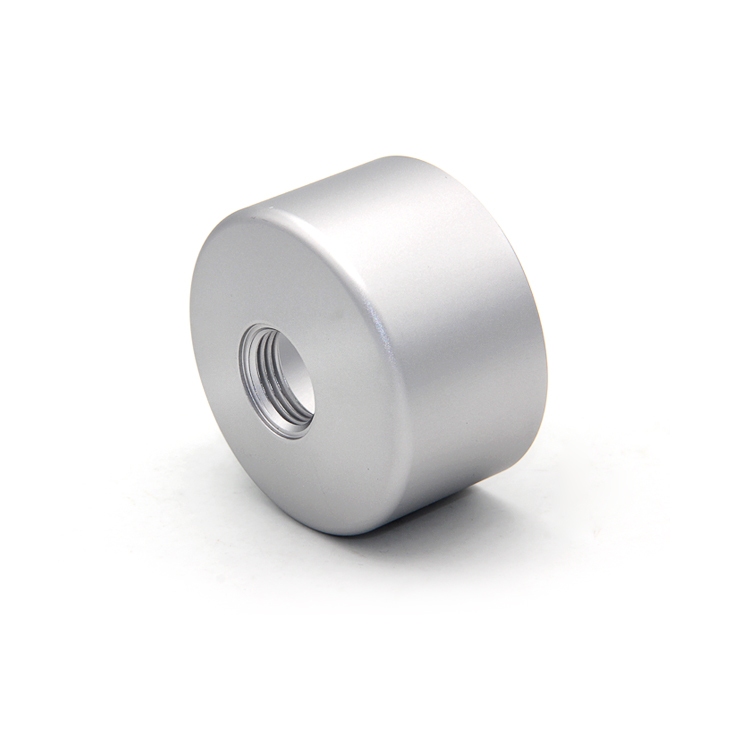

Case Study: Professional landscape lights, architectural lights, stage lights, spotlights, and downlight manufacturers have developed a series of new lighting accessories using our CNC aluminum processing technology. These accessories enable the lamps to not only provide excellent light effects but also have a highly decorative and modern feel. Here are some custom lighting aluminum parts

How to Choose CNC Aluminum Machining Service Supplier

Different CNC machining factories have their own advantages, small factories are suitable for sampling, and large factories are suitable for high volume. In Jiesheng Hardware, flexible production, from small batch production to large scale production, we can do both 30-minute sampling and high volume production for on time delivery.

When choosing a CNC aluminum machining service provider, it is recommended to consider the following aspects:

Machining Capabilities: confirm the supplier's machining capacities, including CNC milling, CNC turning, 5 axis CNC machining and so on

Quality certification: passed international quality management systems certifications, such as ISO 9001 or IATF 16949, which signify that the factory's production and management processes meet high standards.

Experience and expertise: prefer suppliers with years of experience in aluminum machining, with technical and engineering teams that have sufficient expertise to handle complex projects.

OEM ODM service and material selection: confirm whether the supplier can offer OEM ODM CNC machining services, which materials it can provide machining services and surface treatment

Conclusion

Combining the above aspects, you can choose a CNC aluminum processing service supplier that meets your quality requirements, responds quickly and is cost-effective. Jiesheng Hardware makes you feel at ease. From design to product completion, we promise that from the design to the product finish, we promise to give you peace of mind, effort, and cost. You do not worry about receiving the goods and using them.

English

English