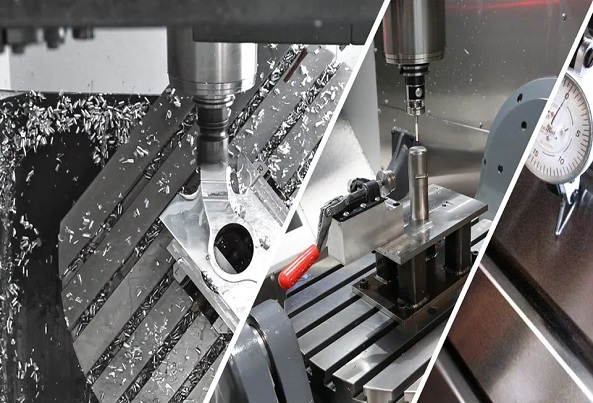

Custom Online CNC Machining Service, or Custom Online Computer Numerical Control (CNC) Machining Service, is an automated machining service that uses computer numerical control technology to shape objects or parts. CNC stands for Computer Numerical Control, which means using computer software to control the movement and operation of the machine.

Features

Automation and Efficiency: CNC Machining is controlled by computer programs, achieving a high degree of automation, which greatly improves machining efficiency.

High Precision: CNC machining can achieve very high machining accuracy and meet the manufacturing needs of various complex parts.

Flexibility: CNC machining can adapt to the machining of parts of different Materials, shapes and sizes, and has strong flexibility.

Online Customization: Users can upload digital models of parts through the online platform, get instant quotes, and quickly get the CNC machined parts they need.

Functions

Digital Model Conversion: CNC machines can only move according to coordinates, so the digital model of the part needs to be converted into a file that CNC can understand, that is, G code.

Automated Machining: Once the CNC machine is configured, you can start automated machining operations without human intervention.

Online Quotation and Ordering: Users can upload part models online, get instant quotes, and directly order the required CNC machined parts online.

The application fields of CNC machining are very wide, including but not limited to:

Automobile manufacturing: CNC machining can efficiently complete various complex shape machining tasks, such as engine cylinders, crankshafts, gears and other key components.

Aerospace field: Aerospace product parts need to go through multiple complex machining processes. CNC machining has high-precision and high-stability machining Capabilities, which can meet the high requirements of product quality and performance in this field.

Mold manufacturing: CNC machine tools play an important role in the mold manufacturing process, and can achieve high-precision and high-efficiency machining of molds.

Machinery manufacturing: CNC machining can realize automated machining through programming, which greatly improves the efficiency and precision of machinery manufacturing.

Electronic manufacturing: In the manufacturing process of electronic products, various small and precise parts need to be processed, and CNC machining can meet this demand.

Medical device manufacturing: Medical device parts need to go through multiple complex machining processes. CNC machining has high-precision and high-stability machining capabilities, which can meet the high requirements of product quality and performance in this field.

In order to ensure the normal operation and extend the service life of CNC processing equipment, regular maintenance and care are required:

Daily maintenance:

Check the lubricating oil level to ensure the lubrication of the machine tool.

Check whether there is enough coolant in the coolant tank, and add it in time if not.

Check the oil level of the pneumatic triplex.

Check the air pressure and adjust it to the set value.

Clean the inner taper of the spindle and spray it with light oil.

Clean the tool magazine arm and tool.

Clear the cutting and oil stains on the workbench, inside the machine tool, and on the three-axis telescopic cover.

Check whether all signal lights and abnormal warning lights are normal.

Clean the machine tool after daily work is completed.

Weekly maintenance:

Clean the air filter, cooling pump, and lubricating oil pump filter of the heat exchanger.

Check whether the tool pull bolt is loose and whether the tool handle is clean.

Check whether the three-axis mechanical origin is offset.

Monthly maintenance:

Check the lubrication of the X, Y, and Z axis tracks.

Check and clean the limit switches and bumpers.

Half-year maintenance:

Disassemble the three-axis chip guard, clean the three-axis oil pipe joint, ball screw, and three-axis limit switch, and check whether they are normal.

Check whether the servo motors and heads of each axis are operating normally.

Replace the oil of the hydraulic unit and the oil of the tool magazine reduction mechanism.

Annual maintenance:

Check whether all buttons are sensitive and normal.

Clean the cutting water tank and replace the cutting fluid.

Periodically check the components such as circuit breakers, contactors, single-phase or three-phase arc extinguishers.

Precautions

Preparation before processing:

Read the drawings and program sheets carefully to ensure that the processing requirements are understood.

Check whether the workpiece reference position is consistent with the drawing reference position.

Determine whether the tool selected by the programmer is reasonable based on the material and size of the workpiece.

Clamping the workpiece and tool:

The workpiece should be clamped firmly to avoid loosening during processing.

The tool should be clamped firmly and not too short to ensure the correct cutting parameters.

Correction and alignment of the workpiece:

When dragging the workpiece, attention must be paid to the verticality.

When centering the workpiece, it must be verified twice.

Precautions during processing:

During processing, closely observe the cutting situation and adjust the cutting parameters in time.

When encountering program abnormalities or tool wear, stop the machine in time for processing.

Precautions after processing:

Confirm that each program and each instruction required by the program sheet have been completed.

After processing, it is necessary to check whether the appearance of the workpiece meets the requirements.

As a supplier manufacturer with a full set of CNC processing equipment, JeaSnn has the following advantages:

Rich processing experience: JeaSnn has many years of CNC processing experience and can provide customers with high-quality processing services.

Advanced processing equipment: JeaSnn is equipped with advanced CNC processing equipment, including multi-axis CNC machine tools, EDM machines, etc., which can meet the processing needs of various complex parts.

Online customization service: JeaSnn provides online customization services. Customers can upload part models through the online platform, get instant quotes, and quickly obtain the required CNC processing parts.

Strict quality control: JeaSnn has a complete quality control system to ensure that every processed part meets customer requirements.

Custom Online CNC Machining Service has been widely used in various fields due to its automation, efficiency, high precision and flexibility. At the same time, in order to ensure the normal operation and extend the service life of CNC machining equipment, regular maintenance and care are required, and relevant precautions must be followed. As a supplier and manufacturer with a full set of CNC machining equipment, JeaSnn can provide customers with high-quality machining services.

English

English