Precision aluminum parts refer to parts made of aluminum and its alloys and produced through high-precision processing technology. Such parts have the characteristics of precise dimensions and high surface finish, which can meet the industrial needs of complex shapes or high performance requirements.

Common aluminum alloys include:

2024 aluminum alloy: high strength and good fatigue performance, suitable for aviation.

6061 aluminum alloy: excellent corrosion resistance and mechanical properties, widely used in industrial machinery and construction.

7075 aluminum alloy: ultra-high strength and good wear resistance, suitable for high-performance sports equipment and aerospace.

Precision and processing requirements

The precision of precision aluminum parts is usually measured by the tolerance range.

The precision of precision aluminum parts is usually measured by the tolerance range.

Linear tolerance: ±0.01mm or less, suitable for shaft and hole parts.

Surface finish: can reach Ra0.8μm or less, ensuring that the surface of the parts is smooth and flawless.

Geometric tolerance: For example, the cylindricality is less than 0.005mm, ensuring that the parts have excellent fit and performance.

Processing requirements

Precision aluminum parts have extremely high requirements for processing equipment, process flow and environmental conditions, and the following conditions need to be met:

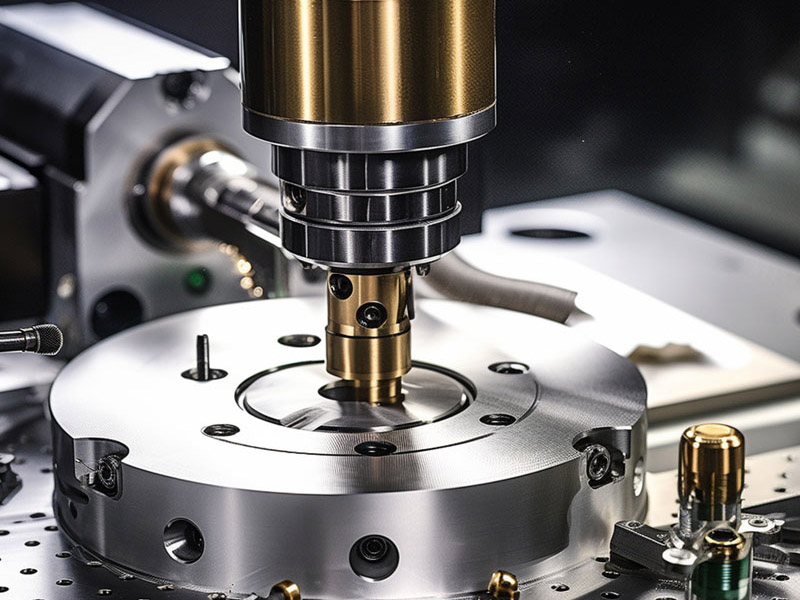

High-precision machine tools (such as CNC Machining centers).

Temperature-controlled environment to avoid the influence of thermal expansion of aluminum on processing accuracy.

Strict quality inspection equipment, such as three-coordinate measuring machines (CMM).

Processing technology

Features: high efficiency and high precision.

Process flow: CNC milling, turning, drilling and tapping, etc., can realize the processing of complex shaped parts.

Application: high-demand parts, such as aerospace components, medical equipment parts.

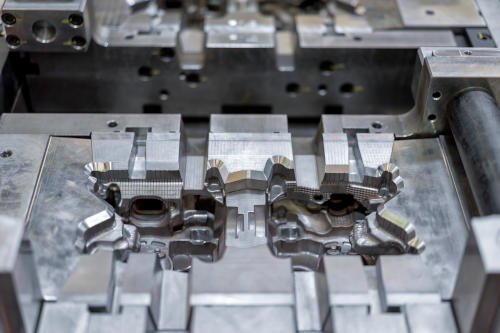

Die casting

Features: suitable for mass production and low cost.

Process flow: aluminum liquid is injected into the mold by high pressure and quickly cooled to form parts.

Application: automotive parts, consumer electronics housing.

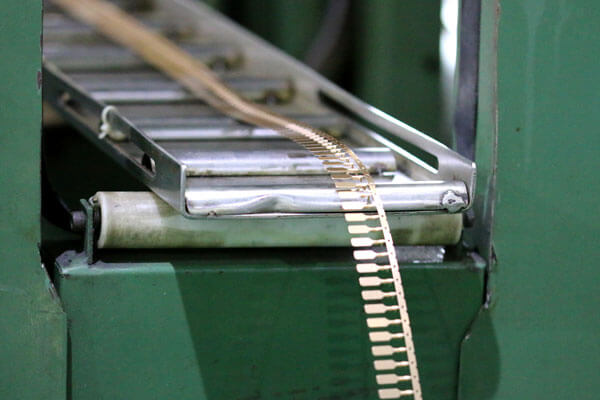

Precision stamping

Features: suitable for the production of thin-walled aluminum parts.

Process flow: aluminum plates are stamped into the desired shape through stamping equipment.

Application: electronic equipment components, decorative aluminum parts.

Surface treatment process

To improve the durability, aesthetics and functionality of parts, common surface treatment processes include:

Anodizing: Enhance corrosion resistance and provide a variety of color options.

Sandblasting: Improve surface roughness or aesthetics.

Electroplating: Increase surface hardness and wear resistance.

The role of precision aluminum parts

Mechanical function: Provide structural support, power transmission or motion control.

Thermal management: Aluminum has excellent thermal conductivity and is often used as a heat sink component.

Weight reduction design: Used to reduce the total weight of the equipment while ensuring strength.

Electromagnetic shielding: In electronic products, aluminum can shield electromagnetic interference.

The characteristics of precision aluminum parts

High strength and light weight: The density of aluminum is only 1/3 of that of steel, but the strength can be significantly improved by alloying, which is suitable for high-strength and lightweight design.

Excellent corrosion resistance: A dense oxide film is easily formed on the surface of aluminum, which can effectively block air and moisture and extend service life.

Good machinability: Aluminum is easy to process, and high-precision cutting and complex shape manufacturing can be achieved.

Recyclability: Aluminum has a very high recycling rate and meets green environmental protection requirements.

Application fields

Aerospace

Aircraft fuselage, engine parts: need to meet high strength and lightweight requirements.

Satellite components: require high precision and durability.

Automotive industry

Engine parts, wheels: need to take into account both strength and heat dissipation performance.

Body structure parts: improve fuel efficiency by reducing weight.

Medical equipment

Surgical instruments: light, antibacterial, easy to disinfect.

Medical imaging equipment parts: require high precision and durability.

Consumer electronics

Mobile phone, notebook shell: light, good thermal conductivity, beautiful appearance.

Radiator: widely used in computers and home appliances.

Industrial manufacturing

Automation equipment parts: need high precision and strong durability.

Mold manufacturing: used for high-precision mold parts.

Energy field

Wind power equipment: lightweight brackets and components.

Photovoltaic power station: aluminum brackets are light and durable.

Precision aluminum parts play an irreplaceable role in modern industry due to their excellent Material properties and extensive processing technology support. Its applications are everywhere, from aerospace to consumer electronics. Through continuous improvement of processing technology and material properties, precision aluminum parts will continue to promote the development of various Industries in the future and become an important driving force for efficiency, environmental protection and innovation.

English

English