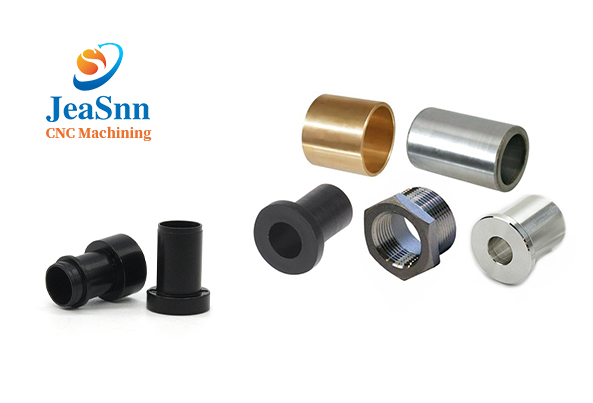

Custom Steel Bushing is a mechanical component made of steel that is used as a lining or sleeve for shafts or other moving parts. It protects shafts or other accessories by reducing friction, extending the service life of equipment and reducing wear. Custom Steel Bushing is customized in size, Material and performance according to specific application requirements and is widely used in Industries such as automobiles, machinery, and construction.

Steel bushings are primarily made from a variety of steel materials, including carbon steel, stainless steel, and alloy steel. The choice of specific material depends on factors such as load requirements, corrosion resistance, and operating environment. Custom steel bushings are designed to ensure that they precisely match other parts of the machine or equipment to provide optimal performance and service life.

Manufacturing process of custom steel bushings

Material selection: First, select the appropriate type of steel. Depending on the required strength, corrosion resistance, and operating conditions, manufacturers can choose materials such as ordinary steel, stainless steel, or alloy steel.

Cutting and forming: After the steel is selected, it is cut into a hollow cylindrical shape by stamping or laser cutting. It is then machined into the required size and shape using turning, grinding, or other mechanical processing methods.

Precision machining: This stage uses automated equipment such as CNC Machine tools to precisely machine the bushing to ensure that the bushing meets the required size and has a high degree of machining accuracy.

Heat treatment: For steel bushings that need to increase strength or wear resistance, heat treatment such as quenching, tempering, or annealing is performed to adjust the hardness and other mechanical properties of the steel.

Surface finishing: Bushings are usually ground, trimmed or polished to ensure a smooth and uniform surface, reduce friction and extend service life.

Surface treatment (if applicable): Depending on the specific application requirements, other surface treatments such as electroplating, lubricating coatings or heat-resistant coatings can also be performed to enhance the corrosion resistance or reduce friction of the bushing.

Quality control and inspection: Each custom steel bushing undergoes rigorous quality inspection to ensure its dimensional accuracy, surface quality and material integrity. Common inspection methods include hardness testing, dimensional measurement and visual inspection.

Tightness of custom steel bushings

Interference fit: In this fit, the size of the bushing is slightly larger than the size of its mounting hole, forming a tight contact. Interference fit is often used in applications that require precise alignment and minimal movement.

Clearance fit: Clearance fit allows a certain amount of clearance between the bushing and the shaft or housing, which is suitable for situations where thermal expansion or movement needs to be accommodated.

Transition fit: This fit is between interference fit and clearance fit, providing some room for movement while maintaining sufficient contact to ensure smooth operation.

The tightness of custom steel bushings is determined during the design phase to ensure that they can handle the load, reduce wear and achieve smooth operation.

Features of custom steel bushings

Durability: Custom steel bushings have high strength and wear resistance, can withstand harsh working environments, and are suitable for heavy-duty applications.

Low friction: The surface of the steel bushing is designed with a low friction layer to reduce friction and wear, improve the working efficiency of the equipment and extend the service life.

Load capacity: Custom steel bushings can withstand different types of loads, including radial loads, axial loads and rotational loads, to adapt to various operating requirements.

Corrosion resistance: Depending on the selected material (such as stainless steel), custom steel bushings can have excellent corrosion resistance and are suitable for applications in humid, chemically corrosive or extreme temperature environments.

Custom design: Through customization, the size, material and performance of the bushing can be precisely adjusted to the specific application to ensure the best working performance.

Versatility: Custom steel bushings are suitable for a wide range of applications, from automobiles and industrial machinery to construction equipment, with strong adaptability and flexibility.

Surface treatment and function of custom steel bushings

Hard chrome plating: A layer of chrome is plated on the surface of the steel bushing to improve wear and corrosion resistance.

Black oxide film coating: This coating can enhance the corrosion and wear resistance of the bushing, especially for environments exposed to moisture.

Phosphating: Phosphating coating can provide a lubricating layer, improve friction characteristics, and enhance corrosion resistance.

Nickel plating: Nickel coating can provide a smooth, hard surface for bushings, improve wear and corrosion resistance, and is suitable for high humidity environments.

Lubricating coating: Some steel bushings are coated with lubricating coatings to reduce friction and ensure long-term reliability under high frequency of use.

Anodizing: For aluminum or anodized steel bushings, the anodizing process can form a protective oxide film on the surface to improve hardness and corrosion resistance.

Application areas

Automotive industry: Steel bushings are used in automotive parts such as suspension systems, steering columns and engine components. Custom steel bushings help reduce friction and wear, improving the durability and performance of vehicles.

Mechanical equipment: Custom steel bushings play an important role in various types of machinery, such as conveyors, industrial robots and heavy equipment, providing shaft support and reducing friction and wear.

Construction industry: In construction machinery (such as excavators and cranes), custom steel bushings are used to connect components and hinge points to withstand heavy loads and harsh working environments.

Agricultural equipment: Steel bushings are often used in agricultural machinery (such as tractors, harvesters, tillers) to help reduce friction and ensure smooth operation under high loads.

Aerospace: In the aerospace field, custom steel bushings are used in key components such as landing gear, actuators and control systems to ensure reliability under extreme pressures and temperatures.

Oil and gas industry: Steel bushings are used in oil drilling equipment, pumps and other heavy machinery to withstand high loads, high temperatures and corrosive environments.

Marine applications: Custom steel bushings are used in propeller shafts, rudder systems and engine components of ships to prevent salt water corrosion and reduce wear.

Mining and Heavy Industry: Steel bushings are used in mining equipment, crushers and conveying systems to help improve durability and ensure smooth operation under high-intensity operations.

Custom steel bushings are key mechanical components in many industries, playing a vital role in various applications due to their characteristics of reducing friction, carrying heavy loads and increasing equipment life. Through precision manufacturing processes, material selection and surface treatment, custom steel bushings can provide optimal performance according to specific needs and ensure long-term stable working performance. Custom steel bushings are widely used in industries such as automotive, machinery, aerospace, construction, oil and gas, and their versatility and customization Capabilities give them great advantages in many fields.

English

English