You can rely on our experience and technical proficiency to meet your specific titanium machining needs efficiently and effectively.

CNC machining ensures the production of titanium parts with precise dimensions, intricate details, and tight tolerances, meeting the most demanding specifications and requirements.

Titanium CNC machining can accommodate a wide range of part sizes, shapes, and complexities, from small intricate components to large structural parts, offering design flexibility and customization options.

Titanium possesses excellent mechanical properties, including high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it suitable for applications in harsh environments and critical applications.

CNC machining offers cost-effective manufacturing solutions for titanium parts, especially for low to medium volume production runs, minimizing material waste and setup costs compared to traditional machining methods.

With efficient CNC programming and automation capabilities, titanium CNC machining services can provide fast turnaround times, enabling rapid prototyping, product development, and production ramp-up.

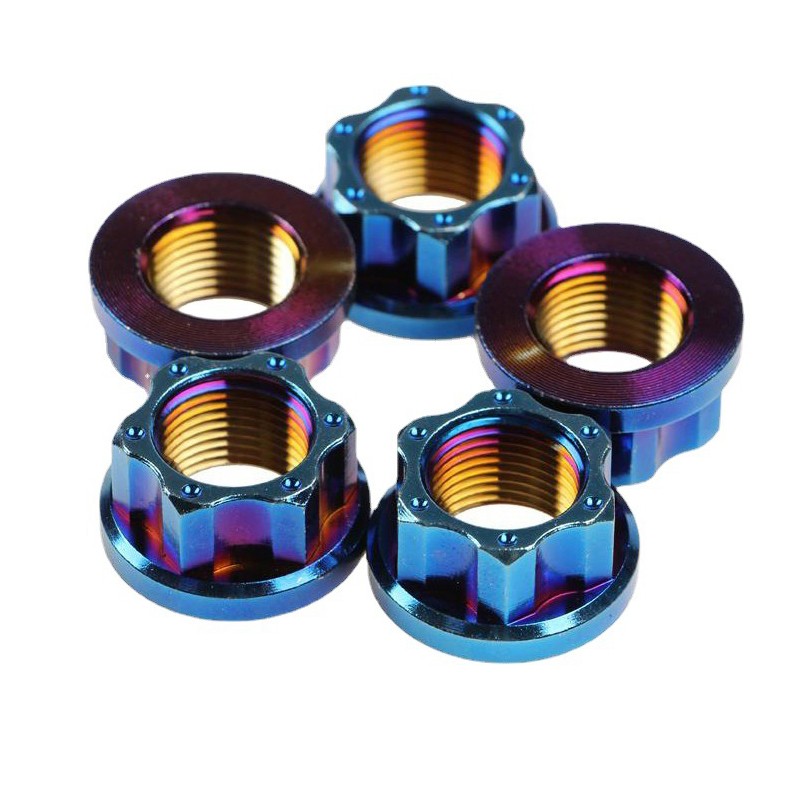

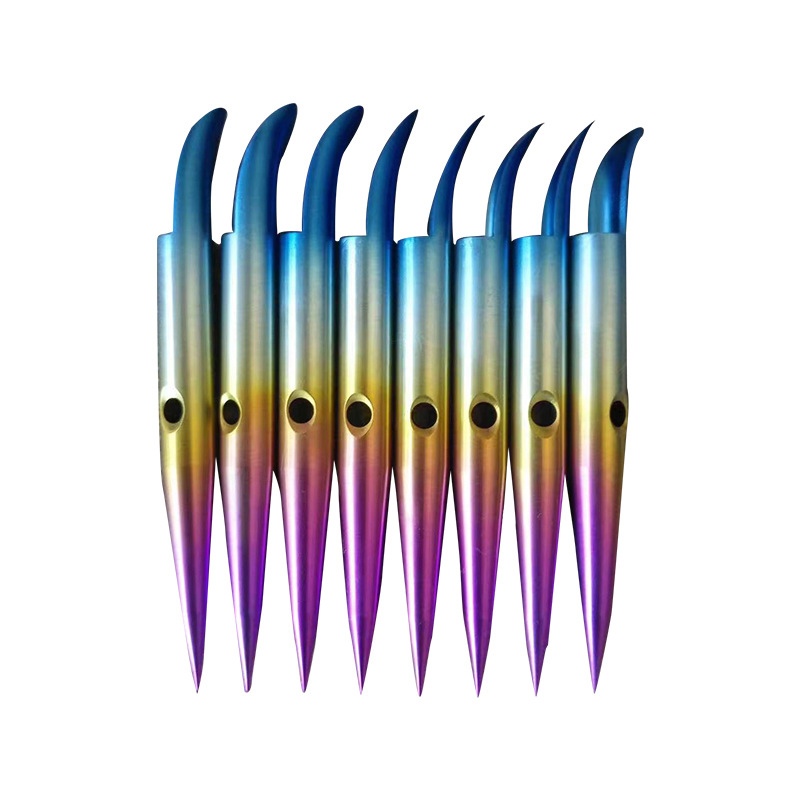

Titanium CNC machined parts can be finished to achieve various surface textures, coatings, and treatments, including polishing, anodizing, plating, and painting, enhancing aesthetics, functionality, and performance.

CNC machining allows for the production of complex geometries and features, such as threads, undercuts, pockets, and contours, which may be challenging or impossible to achieve with conventional machining methods.

CNC machining facilities employ advanced inspection equipment and quality control processes to ensure the highest standards of quality, consistency, and reliability in titanium parts, meeting industry certifications and regulatory requirements.

Machining titanium parts involves various CNC machining processes to shape and form titanium material into finished components. Some common machining types for machined titanium parts include

Aerospace: Titanium's exceptional strength, lightweight properties, and corrosion resistance make it ideal for aerospace applications. Machined titanium parts are used in aircraft structures, engine components, landing gear systems, hydraulic systems, and interior fittings, contributing to fuel efficiency, performance, and durability.

Medical Devices: Titanium's biocompatibility and corrosion resistance make it suitable for medical implants, surgical instruments, and medical device components. Machined titanium parts are used in orthopedic implants (e.g., bone plates, screws), dental implants, cardiovascular devices, and prosthetic limbs, providing long-term reliability and compatibility with the human body.

Automotive: Machined titanium parts are employed in automotive applications to reduce weight, improve fuel efficiency, and enhance performance. Titanium components are used in exhaust systems, suspension components, engine valves, and transmission components, contributing to lightweighting and durability in high-performance vehicles.

· CNC Titanium Parts

· Titanium CNC Parts

· Titanium Machined Parts

· Custom Titanium Parts

· Titanium Stem Bolts