Our experienced engineering and technical teams provide you with tailor-made and highly efficient machining solutions. You can purchase metal products directly from the factory rather than from any secondary source, and we guarantee to deliver them to you as planned and on time.

In steel CNC machining, you can choose different types of steel raw materials based on your design and equipment needs.

Mild Steel

Carbon content is usually less than 0.25%. Easy to machining, cheaper cost. Commonly used in CNC steel parts, steel fasteners and steel sheet parts.

Medium Carbon Steel

Carbon content is 0.25% to 0.6%. It has good strength and toughness and is suitable for parts requiring higher strength. Typical carbon steel parts include CNC machine parts, precision shafts and carbon steel tools.

High Carbon Steel

Carbon content is 0.6% to 1.0%. It has high hardness, but poor toughness and is easily brittle. Suitable for manufacturing knives,tools, springs.

Alloy Steel

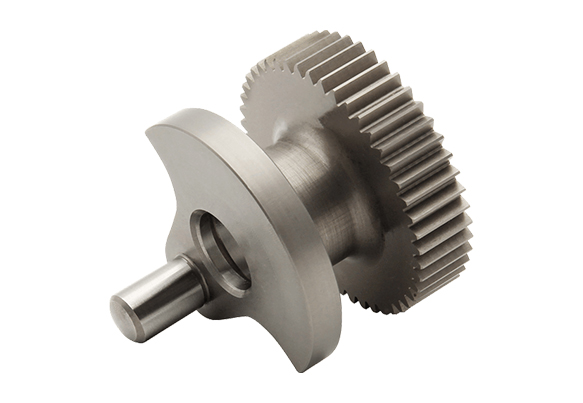

Other elements (such as chromium, nickel, molybdenum, etc.) are added to steel to enhance specific properties. Alloy steel parts has excellent mechanical properties and corrosion resistance. It is often used to manufacture custom CNC parts with high strength, high wear resistance and high heat resistance, such as bearings, gears and aviation parts.

Jiesheng Hardware is a professional manufacturer of customized precision metal parts with more than 20+ years of experience. Give you a wealth of expertise to every precision machining project, ensuring that parts are tailored to match your products.

Jiesheng is committed to customer satisfaction. We strive for continuous improvement in our quality process. We have strict quality control management that is certified by ISO9001:2015 and IATF 16949:2016.

We are 24hrs for your support and offer more professional and reliable advice about steel CNC machining solutions. With instant quotes and rapid production, you can reduce cycle times by as much as 50%.

You design it, we will make it. A Professional R&D team provides one-stop OEM/ODM steel CNC machining service, design service, drawing services, sample services, and assembly services solutions.

We have a sample machining workshop, samples can be ready in as fast as 30 minutes. You will get it in 3 days. We work quickly to ensure your ideas and projects are brought to market quickly and on time.

The packaging of steel precision machined parts is made according to the customer's requirements. It can avoid damage during transportation and save you storage costs. You can put it directly into your warehouse.

An ideal CNC manufacturing solution to help customers minimize costs and maximize benefits. We're lean and efficient and we pass these cost savings onto you.

Make drawings according to the customers' ideas or samples. Make samples for the test before mass production. Acceptable Remote factory inspection /Visit the factory on-site /Assembly service combined shipping.

As a leading CNC machining manufacturer, we have a fully equipped machining workshop that can provide customized steel CNC machining parts with simple or complex geometric shapes. We apply a variety of machining technologies, including CNC milling, CNC turning, CNC turning-milling, CNC Swiss machining or other precision machining services, to ensure that all parts you order are delivered on time and meet your quality expectations.

In Steel CNC machining, surface treatment is an important step to improve the performance and appearance of the machined metal parts. You can choose the appropriate method depending on the application environment, performance requirements and appearance needs of the part.

· Carbon Steel Parts

· Stainless Steel Bolts

· Steel Bushings

· Steel Nuts

· Steel Sleeves

Surface Treatment for CNC Machining Steel Parts

In Steel CNC machining, surface treatment is an important step to improve the performance and appearance of the machined metal parts. You can choose the appropriate method depending on the application environment, performance requirements and appearance needs of the part.

In Steel CNC machining, surface treatment is an important step to improve the performance and appearance of the machined metal parts. You can choose the appropriate method depending on the application environment, performance requirements and appearance needs of the part.

Heat Treatment

Electroplating

Oxidation

Powder Coating

Paint Spraying

Polishing

Sandblasting