303 Stainless Steel

Free-machining grade with improved machinability and chip breakability.

Good corrosion resistance, suitable for general-purpose applications.

304 Stainless Steel

General-purpose grade with good corrosion resistance, formability, and weldability.

Suitable for construction, automotive, kitchenware, and architectural components.

316 Stainless Steel

Enhanced corrosion resistance with molybdenum content.

Higher strength and hardness than 304, suitable for marine and chloride-rich environments.

Biocompatible, used in stainless steel medical device parts and pharmaceutical equipment parts.

17-4 PH Stainless Steel

Precipitation hardening stainless steel with unique strength, corrosion resistance, adjustable hardness and heat treatable for specific mechanical properties for a wide range of applications in aerospace, medical technology and high performance engineering.

Stainless steel can be enhanced with various surface treatments and finishes, including polishing, zinc plating, nickel plating, chrome plating, PVD coating, passivation, brushing, bead blasting and powder coating, to improve its appearance, corrosion resistance, and functional properties for specific applications.

Stainless steel is a popular material for CNC machining due to a combination of its mechanical properties, versatility, and suitability for various applications. Here are some reasons why stainless steel is commonly used in CNC machining:

Stainless steel's primary advantage is its exceptional resistance to corrosion. It can withstand exposure to various corrosive environments and chemicals, making it ideal for applications in harsh conditions such as marine or chemical processing industries.

While maintaining a strong resistance to corrosion, stainless steel also offers high strength, enabling it to endure significant mechanical stresses. This quality makes it suitable for components that bear heavy loads or are subject to high wear and tear.

The durability and resistance properties of stainless steel ensure that components made from this material have a long service life. This durability reduces the need for frequent replacements and is cost-effective over the long term.

Stainless steel can be enhanced with various surface treatments and finishes, including polishing, zinc plating, nickel plating, chrome plating, PVD coating, passivation, brushing, bead blasting and powder coating, to improve its appearance, corrosion resistance, and functional properties for specific applications.

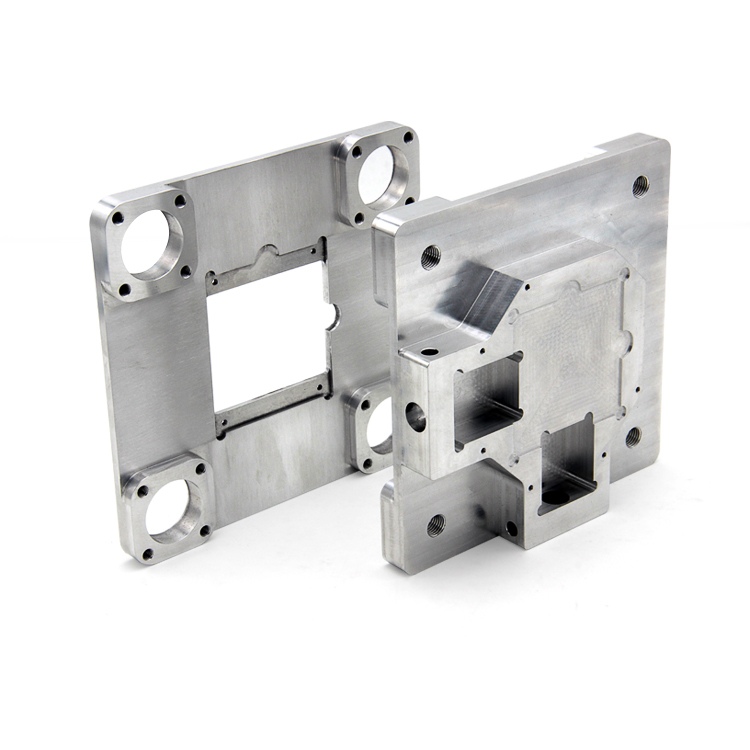

Stainless steel CNC milling

This Stainless steel CNC milling method allows for precise and accurate shaping of stainless steel into complex 2D and 3D geometries, features, and components. You can choose CNC milling, it offers versatility in creating a wide range of parts, from simple shapes and flat surfaces to intricate designs and detailed contours, with high precision, tight tolerances, and excellent surface finishes. We offer stainless steel milling service with 3 axis, 4axis,5 axis cnc manufacturing.

Stainless steel CNC turning

stainless steel CNC turning is particularly well-suited for producing cylindrical components such as shafts, pins, bushings, flanges, and other rotational symmetry parts in stainless steel.

Custom stainless steel parts can be machined to achieve smooth, precise, and high-quality surface finishes, meeting the tight tolerances and aesthetic requirements of various industries, including automotive, electrical, medical, machines and tools.

· CNC Stainless Steel Parts

· Stainless Steel Screws

· Stainless Steel Standoffs

· Stainless Steel Shafts

· Stainless Steel Hex Nuts