Motorcycle modification is indispensable to a variety of high-value, customized aluminum anodized parts, but in the high temperature, outdoor exposure environment, ordinary aluminum anodized parts often about half a year will fade! This is exactly the headache of the motorcycle parts suppliers: what they need is both lightweight, beautiful, and durable metal parts.

Recently, we received an inquiry from a motorcycle modification supplier in Germany. Their goal was to provide a range of colorful and durable motorcycle accessories, JeaSnn’s team was the key support in achieving their goals. We provide metal parts expertise and engineering solutions, let’s take a deeper look at Jiesheng Hardware how to solve the motorcycle anodized aluminum parts fading problem.

These parts are installed close to the motorcycle engine. Under high load operation, especially in racing or extreme conditions, the temperature usually reaches 120℃ to 150℃, or even higher. Some high-performance engines can reach temperatures exceeding 200℃ in extreme situations, especially near the cylinder head. This high temperature can affect the color and surface treatment of nearby parts, so choosing appropriate high-temperature resistant materials and processes is crucial.

High temperature resistance: The product will not change when used in an ultra-high temperature environment. It is necessary to ensure that the durability of the material can withstand extreme temperatures.

Ultraviolet protection: After anodizing, the product will not fade and is durable.

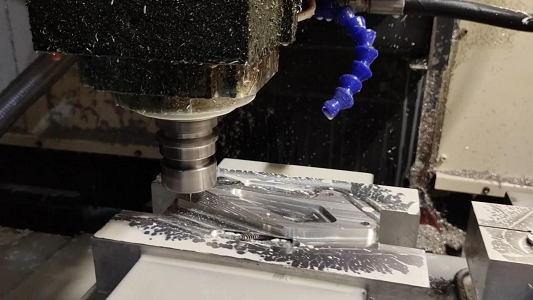

Manufacturing Process: Our engineering team reviewed the part designs and considered the manufacturing methods and ultimately chose CNC milling processing. This ensured that the initial parts were produced with a high surface finish and no tool marks, laying the groundwork for the subsequent anodizing process.

Anodizing Process: The customer requested five colors for each product, black, red, green, orange, and purple. We have learned that this product needs to be used outdoors for a long time in high temperatures, and ordinary anodizing is difficult to meet the working environment of the customer's product. The product needs to be UV resistant and heat-resistant. Our engineers have discussed and decided to change the ordinary anodizing method to UV resistant anodizing, using color powder suitable for outdoor use. After anodizing is completed, each batch of products will be strictly tested by our UV Accelerated Weathering Tester to ensure that they meet the outdoor durability standards before shipment.

The function of UV Accelerated Weathering Tester

This device simulates UV exposure, humidity, and temperature changes to accelerate the aging process of materials, assessing their durability in outdoor or harsh environments. It helps evaluate materials for UV resistance, color fading, strength reduction, and surface cracking. This testing is essential for ensuring product longevity across various fields, including plastics, coatings, adhesives, metals, and automotive components.

In the end, we successfully resolved the fading issue for our client, and they have not received any complaints about anodized parts since.

Project Summary

Through this collaboration, we provided our client with a range of high-temperature resistant and UV-protected anodized aluminum components, significantly improving the performance and appearance of their motorcycle modification products. These enhancements not only addressed previous concerns about fading and damage in high-temperature environments but also ensured long-lasting stability and durability.

For our client, this means they can now offer higher-quality products in the market, enhancing their brand’s competitiveness and improving customer satisfaction and loyalty. This positions them more favorably in a competitive landscape.

As more and more modification suppliers realize the importance of high-temperature and UV resistant treatment, the entire industry will develop towards higher quality, bringing consumers more reliable motorcycle parts.

We believe these innovations will drive growth in the motorcycle modification market, promote technological advancements, and ultimately provide consumers with a safer and better riding experience.

English

English