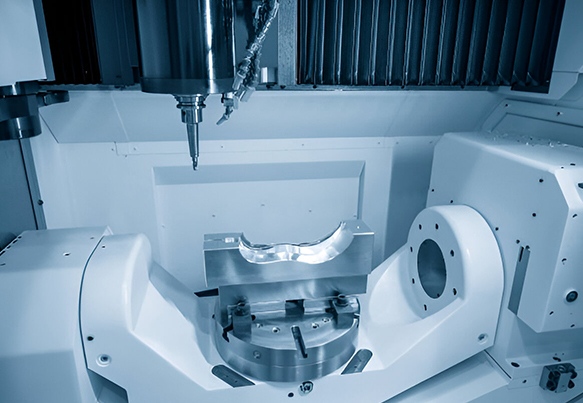

5 axis machining is an advanced CNC machine tool machining technology with five rotary axes that allow positioning and cutting in five degrees of freedom.

Unlike traditional machining methods, 5-axis machining allows us to manipulate a workpiece across five axes of motion, unlocking unparalleled flexibility and complexity in manufacturing processes.

This technology allows two additional rotary axes to be added to the three linear axes (X, Y, and Z), allowing workpieces to be cut and machined in multiple directions. Five-axis machining can handle parts with complex curved surfaces, concave and convex surfaces, curves and spiral shapes, reduce the use of jigs and fixtures, improve the machining accuracy and quality stability of the product, and also reduce the repeated clamping, fixturing and debugging time in the machining process, lowering the labor cost and production cycle time.

We use two outstanding machining methods to provide precise, complex parts, they are Simultaneous 5 Axis CNC Machining and 3+2 Axis CNC Machining

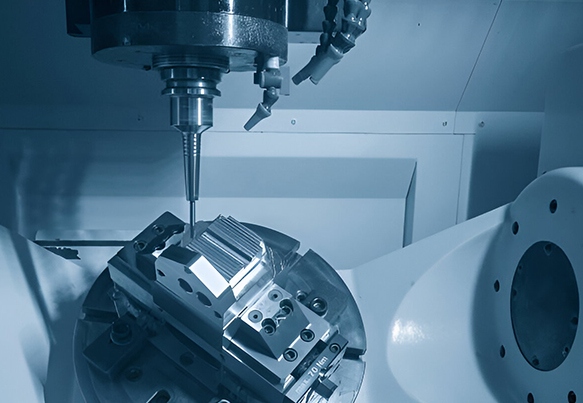

Jiesheng Hardware simultaneous 5-axis CNC machining service offers high precision and accuracy of complex components a versatile and efficient solution for producing

By approaching the workpiece from multiple angles, simultaneous 5-axis machining ensures better surface finish and dimensional accuracy, particularly for CNC parts with intricate geometries.

The ability to tilt and rotate the workpiece simultaneously opens up new possibilities for machining complex features such as undercuts, contours, and compound angles.

3+2 axis CNC machining, also known as indexed 5-axis machining, combines the capabilities of 3-axis machining with additional positioning axes to achieve complex geometries.

We 3+2 axis CNC machining uses shorter and more rigid cutting tools to offer your parts better dimensional stability and simplify programming and improve production efficiency, save time and reduce costs and deliver on time and quickly.

Get your custom machining parts and prototypes with tight tolerances.

![]()

Jiesheng Hardware, which is a professional manufacturer of customized precision metal parts with more than 20+ years of experience. Give you a wealth of expertise to every precision machining project, ensuring that parts are tailored to match your products.

We have a sample machining workshop, samples can be ready in as fast as 30 minutes. You will get it in 3 days. We work quickly to ensure your ideas and projects are brought to market quickly and on-time.

Jiesheng is committed to customer satisfaction. We strive for continuous improvement in our quality process. We has strict quality control management that is certified by ISO9001:2015 and IATF 16949:2016.

We are 24hrs for your support, offer more professional and reliable advice about cnc machining solutions. With instant quotes and rapid production, you can reduce cycle times by as much as 50%.

![]()

You design it, we will make it. A Professional R&D team provide OEM/ODM CNC machining design service, drawing services, sample services, assembly services solutions.

![]()

The packaging of precision machined parts is made according to the customer's requirements.It can avoid damage during transportation and save you storage costs. You can put it directly into your warehouse.

![]()

An ideal CNC manufacturing solution to help customers minimize costs and maximize benefits. We're lean and efficient and we pass these cost savings onto you.

Make drawings according to the customers' idea or samples. Make samples for the test before mass production. Acceptable Remote factory inspection /Visit the factory on-site /Assembly service combined shipping.

We understand that every project is unique. That's why we offer customizable solutions tailored to your specific requirements. Contact us today to learn more about how our custom 5-axis CNC machining services can benefit your business.

JeaSnn is the preferred choice for precision 5 axis CNC machining. Established in the industry with strict quality standards. Quality is the foundation of our survival. Our highly skilled engineers and technicians strictly control every detail and every process is refined. With ISO 9001:2015 and IATF 16949:2016 certifications and a quality control process of comprehensive, you can trust us to deliver superior quality with your five axis machining parts project.

There are a wide variety of materials that can be machined using CNC technology, JeaSnn provides CNC machining quotes for more than 50 engineering-grade plastic and metal materials. In terms of finishes, various types of surface finishes can be applied to CNC machined parts.

Aluminum, Brass, Copper, Stainless Steel, Bronze, Steel, Carbon Steel, Titanium Etc.

Machining Aluminum Parts

2024, 5052,5083, 6061,6061-T6, 6063,6082, 7075, etc.

Machining Stainless Steel/Steel Parts

SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Machining Brass/Copper/Bronze Parts

HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Machining Plastic Parts

PTFE, PTFE, Teflon, ABS, PC, PA, Nylon, POM, Acetal, Delrin, PVC, HDPE, PEEK, Ultem.

We support one-stop CNC machining surface finishing to meet the visual and functional requirements of any design. Including anodizing, sandblasting, electrophoresis, polishing, mirror polishing, painting, printing, laser etching, anodizing, electroplating, nickel plating, chrome plating, powder coating, electroplating, black oxide, brushing, passivation, heat treatment etc.