JIESHENG HARDWARE is a professional manufacturer that focuses on customizing high precision hardware spare parts with more than 20 years of experience.We are an expert in machine parts solutions, like CNC Machines, Oilfield Equipment, Sensors,3D Printer,CNC Router, Automobile and Electrical Equipment, etc.The materials include stainless steel, aluminum, steel, brass, copper, bronze, POM and other materials. Surface treatment: anodizing, polishing, electrophoresis, electroplating, black oxide, brushing, passivation, heat treatment, powder coated etc.

20+ years experience in OEM ODM precision metal parts manufacturing.

Sample ready in as fast as 30 minutes.

ISO 9001:2015 and IATF16949:2016 quality system certification.

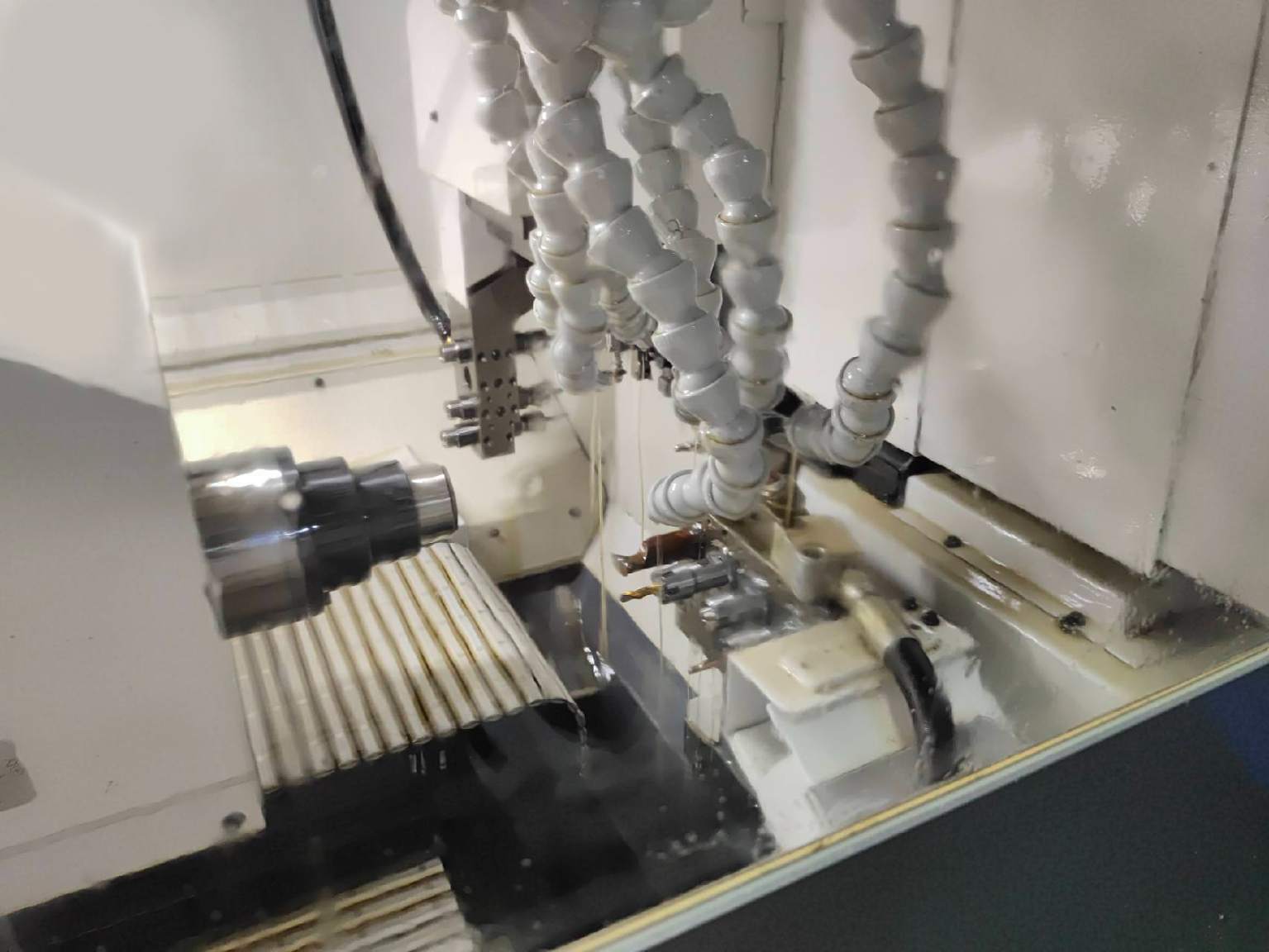

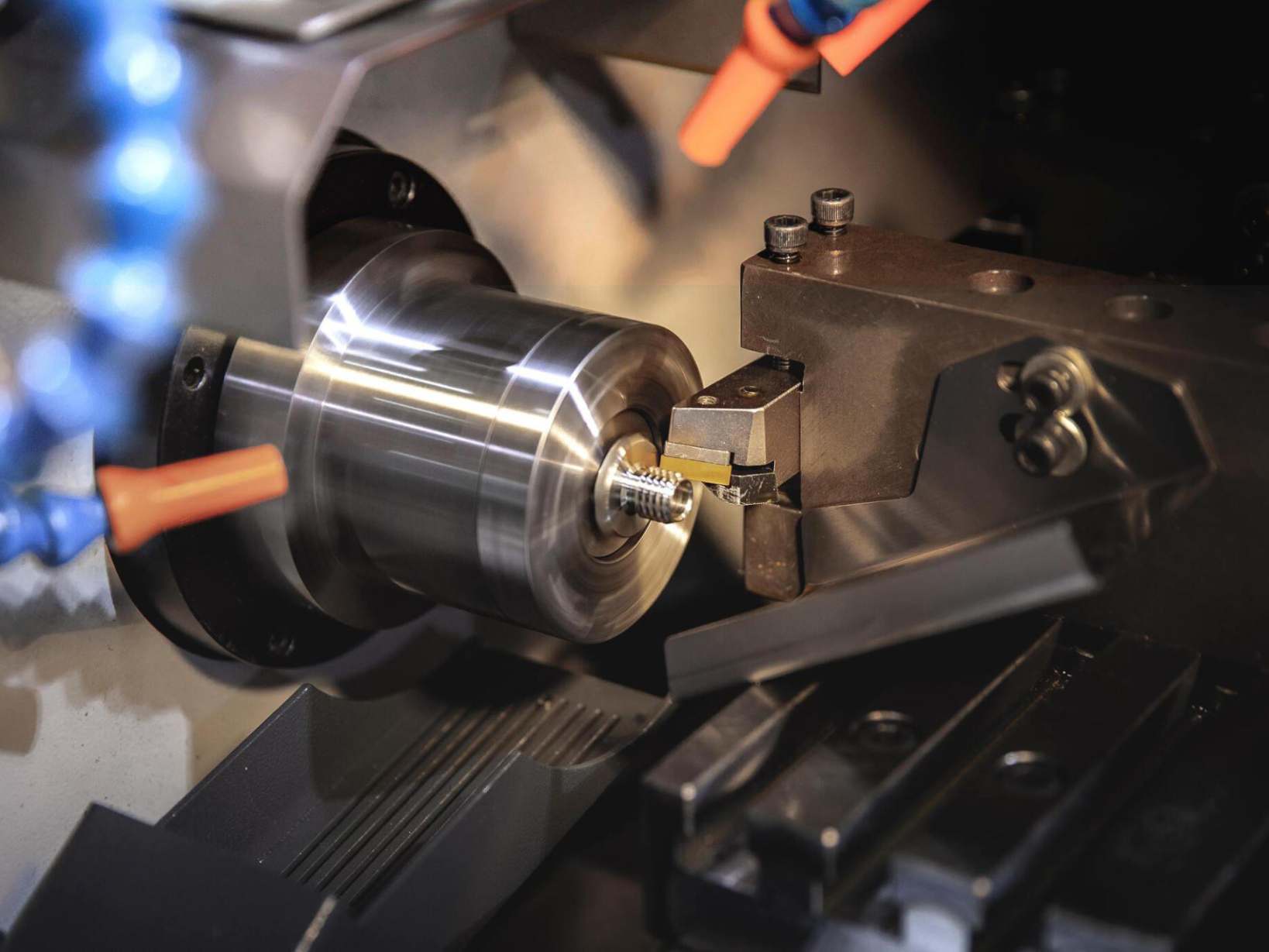

Our machines are imported from Japan tolerances of our products can meet +/-0.005mm, including CNC lathe machines, CNC milling machines, automatic lathe machines, screw machines and so on.

Flexible volumes, ranging from Small Batch Production to Mass Manufacturing.

Accommodating approach vectors for complex geometry from any angle.

☛Solve your problem with custom precision hardware spare parts.

☛To provide you with the best product support, the perfect cost

☛Help you develop and win more markets share on your side.

☛From the design to the product finish, we promise to give you peace of mind, effort, and cost. You do not worry about that receiving the goods and using them.

Our machining facilities run lean and efficiently, with each employee contributing to the shop’s success in important, but different, ways. Let’s take a look!

60+ Employees

To ensure the production goes well efficiently. we maintain a high degree of accountability both to our customers. The loyalty and commitment of our employees means our customers are benefiting from many years of experience in producing custom precision metal parts.

4 senior Engineer -Engineering Department

Professional engineers team provides customers with good OEM solutions. Review the part design to determine the fixture design, taking into account all critical features as well as the project’s budget. Lean and efficient and we pass these cost-savings onto you.

5 QC-Quality Department

To make sure every order from our company with good quality. Quality control is carried out throughout the manufacturing process. Precision inspecting equipment, such as CMM, to ensure that parts conform to customer drawings.

Manufacturing Services for Metal & Plastic Parts

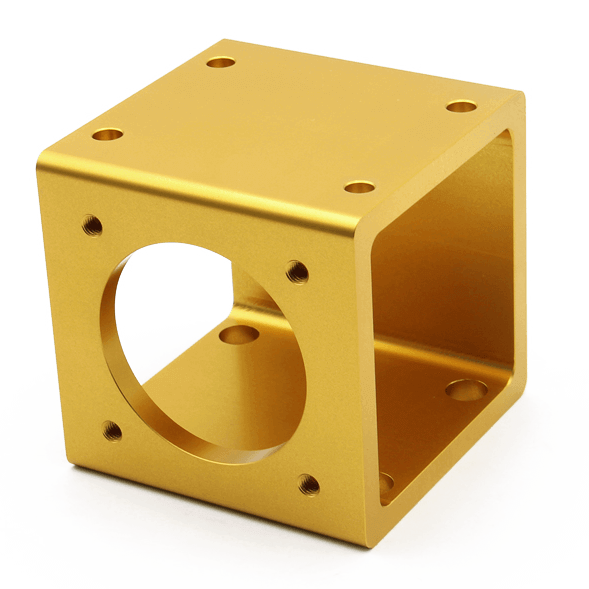

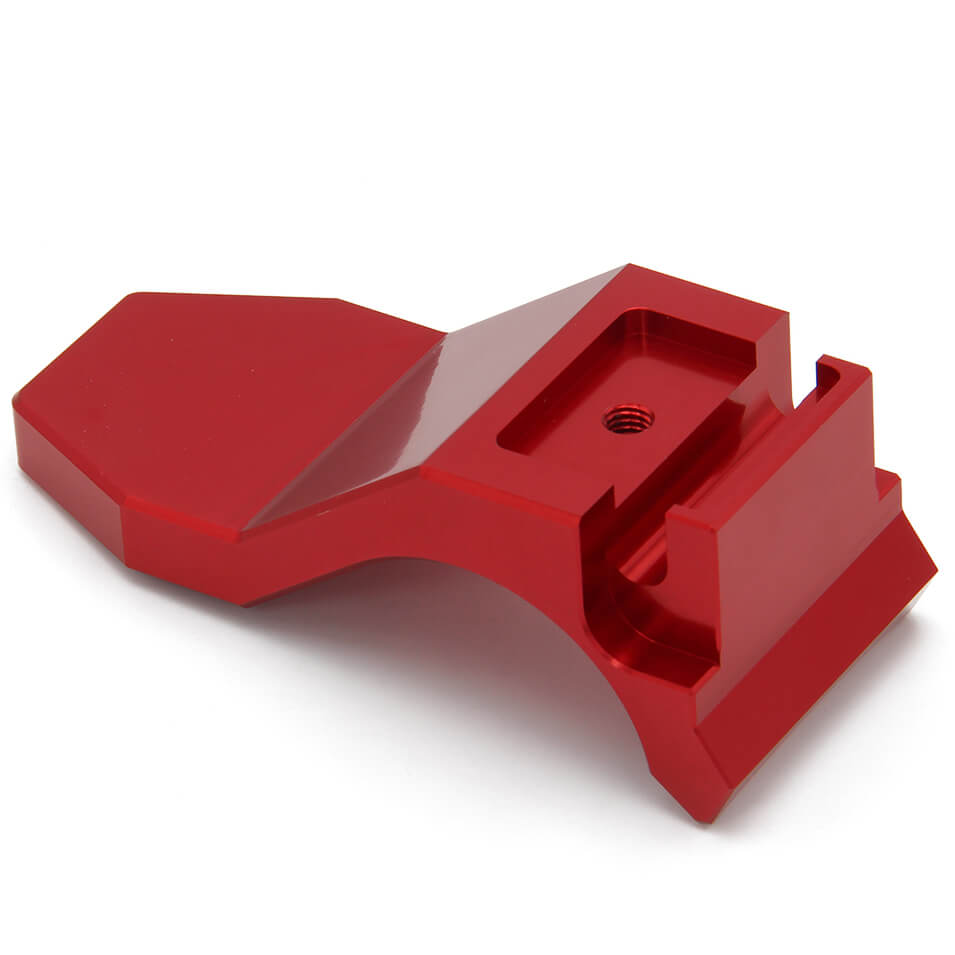

Machining Aluminum Parts

Material: 2024, 5052,5083, 6061,6061-T6, 6063,6082, 7075, etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: oxidation, electrophoresis, sandblasting, electroplating, chemical treatment, painting, hard anodizing, heat treatment, etc.

Machining Stainless Steel / Steel Parts

Material: SUS303,SUS304,SS316,SS316L,420,430,17-4PH,1214L/1215/4140/SCM440/40CrMo, etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment, pickling, shot peening, etc.

Machining Brass / Copper / Bronze Parts

Material: HPb63, HPb62, HPb61, HPb59, H59,H62,H63,H65,H68, H70,H80, H90, C110, C120, C220, C260, C280, C360 etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment, pickling, shot peening, etc.

Machining Plastic Parts

Material: Acetal/POM/PA/Nylon/PC/PMMA/PP/PVC/PU/HDPE/PVDF/Acrylic/ABS/PTFE/PEEK etc.

Tolerance: +/- 0.01~0.005mm

Surface treatment: spraying, sandblasting, painting, pickling, alkali cleaning, anodizing, ion implantation, thermal transfer printing, engraving, etc.

Our Packaging Capabilities

The precision machined parts and components packaging is made according to the customer's requirement.

Quality Assurance of Custom Metal Parts

As an ISO 9001: 2015 and IATF 16949: 2016 certified company, These process standards enable us to meet stringent customer requirements for a wide range of industries. Jiesheng Hardware is determined to deliver a level of service that consistently exceeds the expectations of those who have entrusted us with their business. We are continually improving our procedures, our products and our technology so that every order and any demand results in total customer satisfaction. Because we know quality and dependability are of vital importance, our experienced Quality Control personnel thoroughly inspect all products using carefully maintained measuring equipment and by conducting a series of demanding tests.

|

Years in CNC Machining

Production Equipments

Factory Square Meters

Trusted Clients